- Press Releases

- Industry Updates

- SIMTech Manufacturing Matters

- Manufacturing Matters

- SIMTech 30th Anniversary

- Events

- ASPEN2022

- BCA Green Mark (Platinum) for Healthier Workplaces and Laboratories

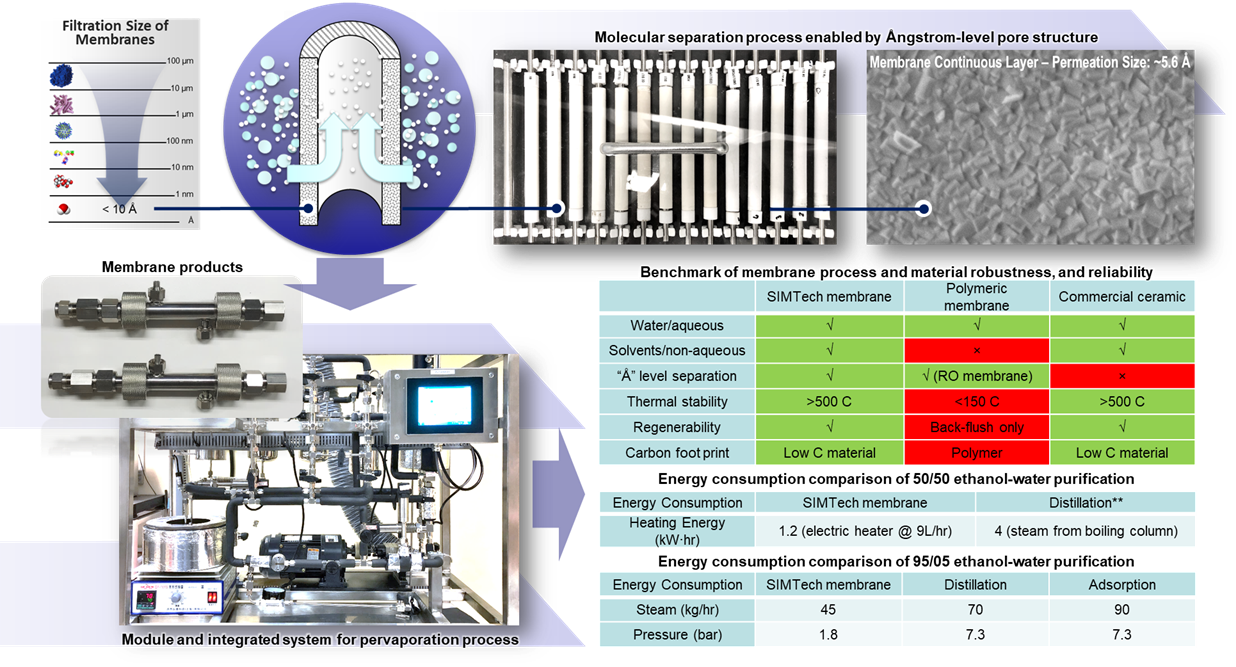

Technology to Improve Resource Circularity and Reduce Waste

New membranes for non-aqueous and gaseous molecular filtration developed

The research team, led by SIMTech researcher Dr Dong Xuecheng (second from left), developed the membrane technology and pervaporation system for solvent separation

Waste reduction from chemical processes is becoming increasingly important as we move towards a green and sustainable circular economy. With an increase in environmental awareness and regulations, the emphasis shifted from end-of-pipe treatment to reduction of waste at source over time through resource circularity by reusing and recycling raw materials. Membrane separation technologies can be employed to help minimise industrial waste, wastewater and effluent. Now, improvised methods of micro and nano-level separation are developed to contribute towards a more effective waste treatment.

Membrane separation is a cost-effective technology to separate various mixtures of liquid materials, and can be applied to aqueous, solvents and gaseous streams. Through reusing, recovering and recycling of water and raw materials from process streams, waste can be minimised, and therefore bring about energy savings and cost savings.

SIMTech’s novel membranes provide a number of significant advantages over polymeric membranes in terms of the process and material robustness, and reliability

SIMTech’s membrane provides angstrom level porosity for non-aqueous and gaseous molecular filtration

Currently, polymeric membranes in both hollow-fibre and flat-sheet configurations have dominated the membrane market as it is energy-efficient and low-cost. While polymeric membranes function well in water applications, its

effectiveness is very limited when it comes to separating complex mixtures, or when operated under high temperatures and extreme conditions.

As compared to polymeric membranes, the membranes developed by SIMTech are able to resist high temperatures and can be used for solvents and non-aqueous filtration.

Many industry sectors such as the pharmaceutical, biomedical, food and beverage, and petrochemical industries, can tap on this technology to improve their resource circularity and manufacturing sustainability, and at the same time

reduce energy consumption, carbon footprint and waste.

For enquiries, please contact

Dr Ng Sum Huan Gary, Acting Deputy Director, SEAC

Email: shng@SIMTech.a-star.edu.sg

![]()

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)