FEATURES

Waste-To-Resource Reverse Logistics Platform

Facilitating B2B Waste-To-Resource Operations For Circular Economies

Left: Alpha Biofuels collects used cooking oil as feedstock for biodiesel production

Right: Collection of used cooking oil at Alpha Biofuels partner site

How is SIMTech working to help Singapore achieve her national goal of net zero carbon emissions within the century? Meet our Waste-to-Resource Reverse Logistics Platform, a digital resource management system in the circular economy that connects businesses through a waste-to-resource matching algorithm that automatically shortlists potential partners to be matched for efficient coordination of operations. This platform also conducts environmental impact evaluations, calculating companies’ net carbon footprint, and monitoring and reporting environmental impact, thereby delivering a complete systems solution to support local companies in waste upcycling.

One such local SME is Alpha Biofuels (Singapore) Pte Ltd, helmed by Allan Lim and Jack Ling, who own and operate the only waste-to-biodiesel plant in Singapore and supply these low carbon biodiesels to local logistics and construction industries as well as international bunkering companies. Alpha Biofuels derives feedstock for biodiesel production in the form of used cooking oil collected from Singapore’s domestic food and beverage (F&B) industry. This precious feedstock is then converted into biodiesel at Alpha Biofuels’ plant in Tuas, Singapore through a series of complex processes to arrive at a biodiesel that adheres to international standards on quality (EN14214) and sustainability (ISCC.EU). This upcycling process not only reduces waste output by our F&B industry while providing a source of biofuels, but also enriches the local economy by allowing F&B owners to get paid for their used cooking oil, as well as reduces our import burden and improves energy security by utilising locally-sourced feedstock.

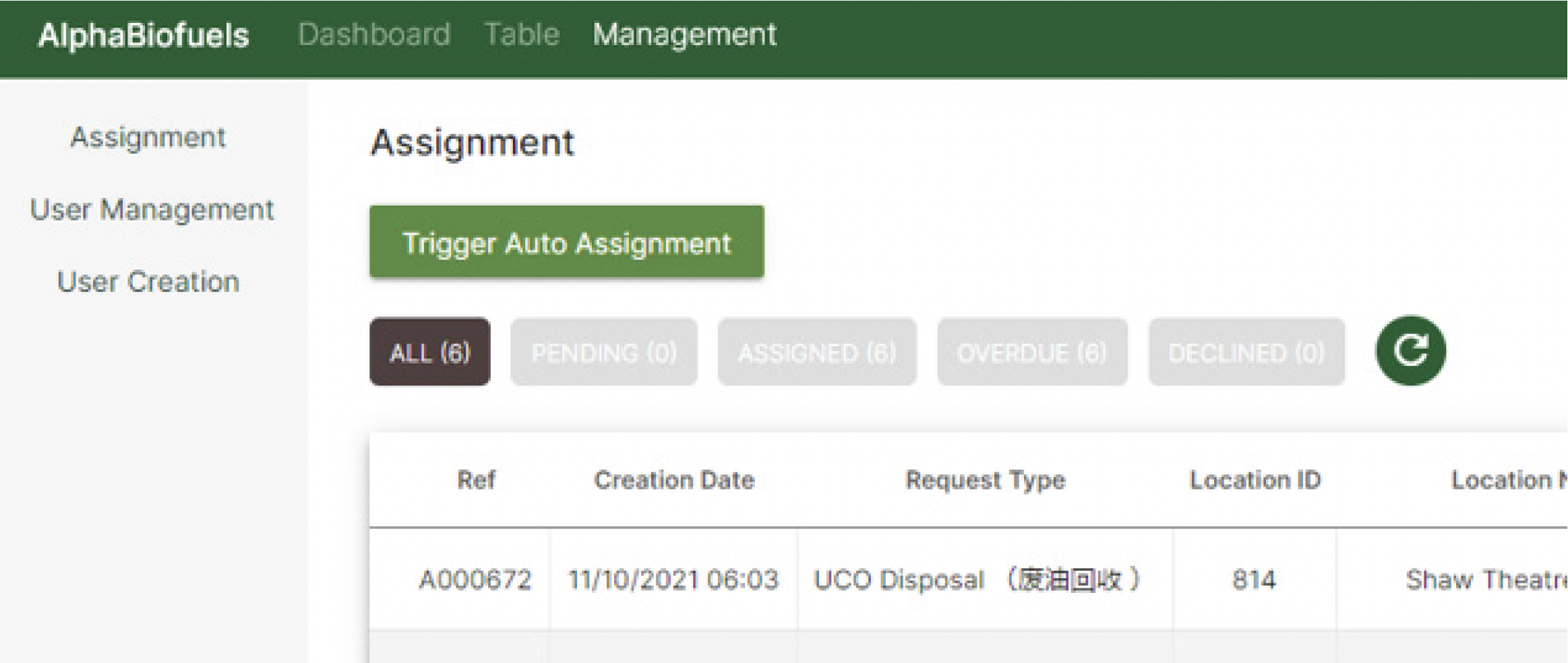

Waste-To-Resource Reverse Logistics Platform - Management Dashboard

However, there were various challenges in this upcycling process. Scalability was an issue due to tedious waste-to-resource manual coordination required between multiple parties, as well as availability constraints. There was also a lack of transparency in this workflow and the environmental benefits were not well reflected.

SIMTech’s Waste-to-Resource Reverse Logistics Platform provides Alpha Biofuels with a digital resource management system that enables the SME to coordinate resource matching efforts, access a high level of traceability and conduct environmental impact evaluations of carbon footprints from network to individual business levels. This also facilitates scalability in its business operations, propelling it onward in its mission to help individuals and communities reduce their carbon footprints and derive clean energy from waste.

Alpha Biofuels aims to produce cost efficient biofuels with the lowest possible carbon footprint so that its customers will have a competitive advantage in sustainability. The platform will help drive down the cost of sustainable feedstock and set the first example of a circular economy in Singapore. It will also enhance our capability to collect used cooking oil without incurring a heavy carbon footprint in transportation; we hope this new capability will enable us to produce biodiesel with the lowest carbon footprint in the world.

Mr Allan Lim, CEO, Alpha Biofuels

For enquiries, please contact

Dr Ng Sum Huan Gary, Acting Director, SEAC

Email: shng@SIMTech.a-star.edu.sg

![]()

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)