Stronger Alloy with Additive Manufacturing

15 Jan 2020

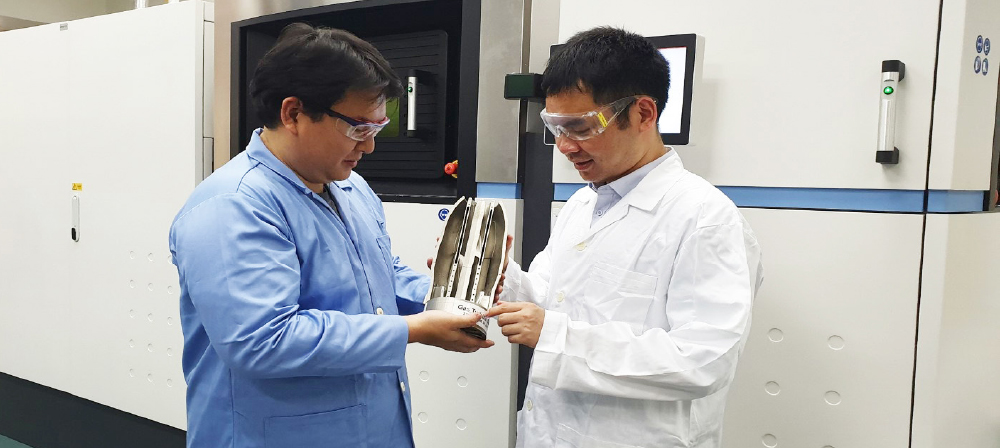

Paving a new way of manufacturing using Selective Laser Melting and Electron Beam Melting

High entropy alloys (HEAs) are a new class of materials with at least five elements in similar atomic proportions that have received significant attention in the last decade due to their outstanding strength and corrosion resistance. Typically, HEAs are produced through multi-step processing techniques by deforming and heating the material, resulting in high processing cost and difficulty in achieving near net shape products. To enable the adoption of such alloys, the SIMTech team used two types of 3D powder bed printing processes – Selective Laser Melting (SLM) and Electron Beam Melting (EBM) to manufacture a prototype CoCrFeNiMn HEA product. These layer-by-layer assembly by 3D powder bed printing provides vast design freedom and product customisation to tailor to specific applications.

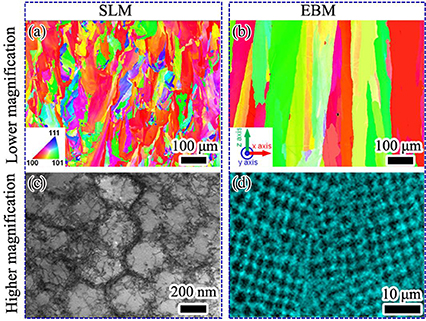

Figure 1: The electron backscattered diffraction (EBSD) image of the (a) SLM and (b) EBM fabricated CoCrFeNiMn HEA at lower magnifications. (c) The cellular structure of the SLM processed HEA shows high density of dislocations along the boundary. (d) The energy dispersive spectroscopy (EDS) mapping shows the segregation of Mn along the cellular boundary

The control of cooling rates during solidification of the layered CoCrFeNiMn powders during 3D powder bed printing technique yields unique microstructures and mechanical properties that are not readily achieved via conventional casting or forging technologies, such as a hierarchical microstructure and higher strength.

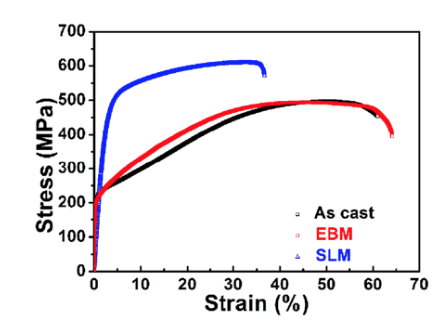

The SLM processed alloy exhibits finer grains and sub-grains as well as a higher dislocation densities decorating along the sub-grain boundary as compared to those of EBM processed alloy due to the faster cooling rate associated with the SLM process (see Figure 1). As a result of the obtained microstructures, the SLM processed alloy is stronger than that of the cast counterparts while the EBM processed alloy is as ductile as that of cast samples (see Figure 2). It is anticipated that the microstructures and properties of the 3D powder bed printed HEAs can be further tailored through controlling printing conditions and post-heat treatment. For instance, the strength of the SLM fabricated HEA could be tailored through manipulating the defect density – dislocation density.

Figure 2: The tensile properties of the SLM/EBM fabricated and cast CoCrFeNiMn HEAs

The successful demonstration of high-performance powder bed printed HEA with tailored mechanical properties, can provide a new insight to design HEAs with customised properties to meet specific industrial demands

In recognition of its scientific novelty and potential applications, the work has been published in the Scripta Materialia and Materials & Design, and reported by some technology media.