Direct Deposition 3D Printing for Manufacturing & Remanufacturing* (40 Hours)

Introduction

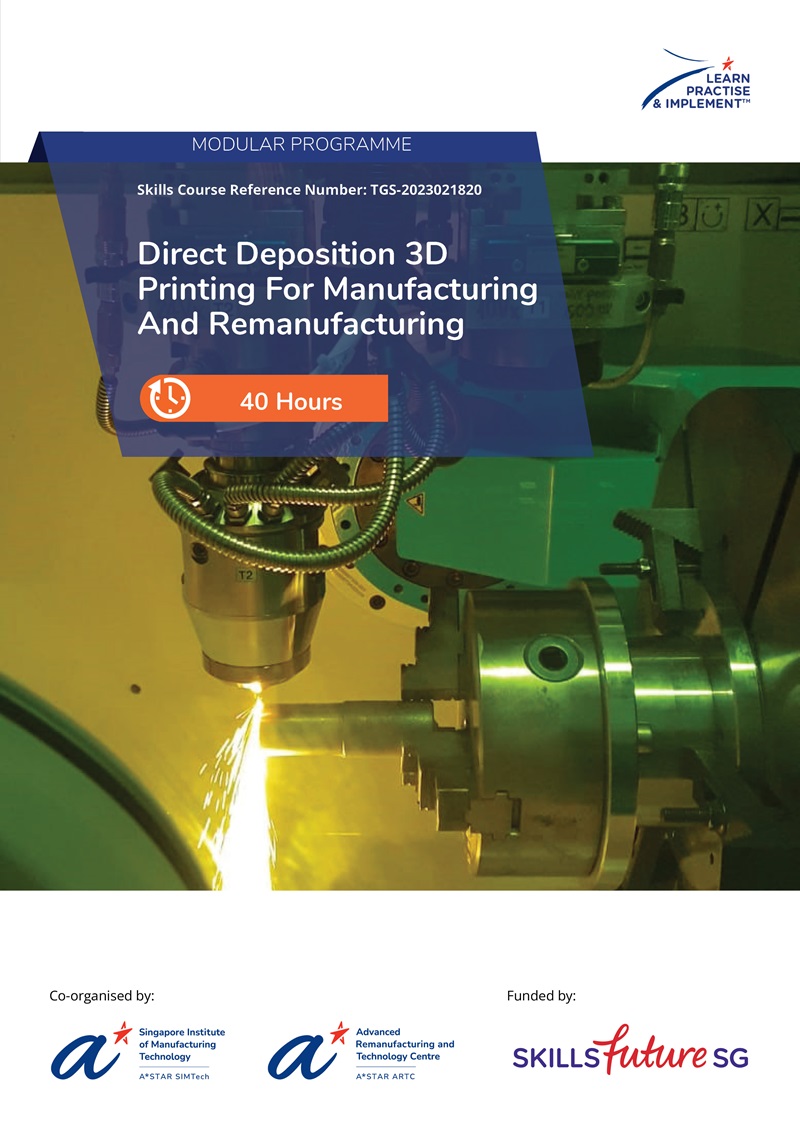

Additive manufacturing, commonly coined as ‘3D printing’, is an increasingly popular technology for the new age Digital Manufacturing involving the generation of parts and features from computer-aided drawings (CAD) in a typical layer by layer manner using various forms of materials from metals to polymers. A direct deposition is one of the many forms of additive manufacturing and in this course, the focus is on the laser blown powder technique for the manufacturing and/or remanufacturing of metal-based components – where a laser is used to melt metal powders delivered by a flowing gas to form first a melt pool which solidifies to create layers of deposition on a workpiece. It is synonymous with laser welding with a powder feedstock. This free-form fabrication method can be employed for a wide range of generative and regenerative applications such as feature addition and/or repair of components, coatings for functional purposes, on top of new component manufacturing, and across various industries – aerospace, automotive, marine and offshore, energy and infrastructure, heavy machinery, etc.

About the Programme

This course consists of theory-based lessons as well as practical hands-on activities on industrial machines available at the designated training site – which, unless under special circumstances, is the A*STAR’s Advanced Remanufacturing and Technology Centre (ARTC) located within the Nanyang Technological University campus at JTC CleanTech Two.

Participants will be able to:

- Learn the fundamentals of direct deposition and the laser blown powder (LBP) process – underlying concepts, key process inputs and outputs, system technology, and possible applications

- Gain practical skills in the required programming, as well as pre-and post-process activities to generate simple build geometries

- Acquire the know-how to draw input-output relations and in perform first-pass quality assessments for an actual deposition process

- Learn key process risks/hazards and best practises pertaining to system and operational health, safety and environment (HSE), as well as gain knowledge on the necessary licences and approvals to run an LBP process

Who Should Attend

This course is targeted at organisations and/or individuals looking to have the first understanding or to develop the capability of the direct deposition method for manufacturing and/or remanufacturing applications. It is also suitable for those who are currently employed or who wish to be employed in manufacturing-related fields with the typical candidate profiles being but not limited to the following:

- Process technician/engineer

- Production supervisor/manager

- Quality control manager/engineer

What Our Trainees Say

Fruitful learning journey. Great facility and environment for learning. Trainers are approachable, knowledgeable and engaging. Awesome experience!

Mr Ronald Foo,

Participant from Nov 2024 intake

About The Trainers

Dr Alin Patran

Ms Grace Tay

Contact Us

- For technical enquiries, please contact:

Dr CHEW Youxiang,

Email: chew_youxiang@a-star.edu.sg

- For general enquiries, please contact:

Knowledge Transfer Office,

Email: KTO-enquiry@a-star.edu.sg

Registration

- Please register for this course through our online form: Course Registration Form for Public Classes.

- For the first question, please select "Modular Programmes (Standalone Modules)".

- Applicants will be placed on our waiting list if the course does not have an upcoming scheduled intake.

- When the next intake is confirmed, a confirmation email with payment information will be sent to applicants to finalise their participation.

Schedule

Module | Skills Course Reference Number | Next Intake(s)' Training Period

(Click on the dates to view their schedules) | Registration Status |

| TGS-2023021820 | The schedule for the next intake is still in the planning stage. |

Note: A*STAR SIMTech and A*STAR ARTC reserve the right to change the class/schedule/course fee or any details about the course without prior notice to the participants.

Announcement:

- From 1 Oct 2023, attendance-taking for SkillsFuture Singapore (SSG)'s funded courses must be done digitally via the Singpass App. More information may be viewed here.

- Participants will be provided with digital course materials when attending our courses. Please note that printed copies will not be available.

: Full day

: Full day : Morning

: Morning : Afternoon

: Afternoon : Evening

: EveningQuick Link

- View the full list of modular programmes offered by A*STAR SIMTech and A*STAR ARTC.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)