- Press Releases

- Industry Updates

- SIMTech Manufacturing Matters

- Manufacturing Matters

- SIMTech 30th Anniversary

- Events

- ASPEN2022

- BCA Green Mark (Platinum) for Healthier Workplaces and Laboratories

SIA*SIAEC*SIMTech Joint Lab

Accelerated collaboration in response to COVID-19

In July 2019, a joint laboratory was set up between Singapore Airlines (SIA), SIA Engineering Company (SIAEC) and SIMTech. This tripartite collaboration aimed to accomplish the following goals: (1) to develop local manufacturing capabilities for aircraft cabin interior components with improved product performance, reduced cost and component lead time; (2) to enhance the local manufacturing ecosystem for aircraft cabin interior components by uplifting SMEs capabilities and helping them to move up the value chain and (3) to provide manpower training to support the local aerospace cabin interior manufacturing workforce. The established local supply chain and ecosystem will help Singapore become the R&D Centre of Excellence for cabin interior components design and manufacturing.

Anticipating the uptick in travel demand upon reopening of country borders, two projects were recently completed by the joint laboratory to provide new cabin fixtures that help to combat the pandemic. The rapid deployment of these two projects demonstrates how product development could be accelerated by adopting advanced technologies.

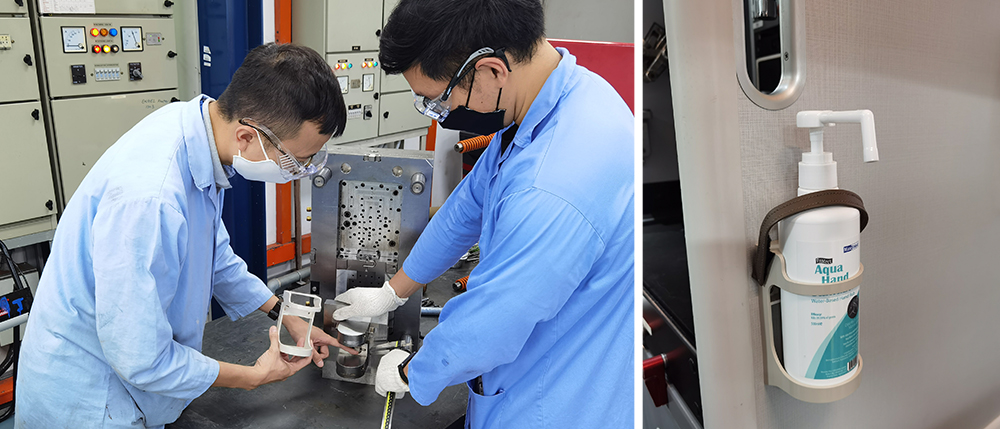

Project 1 - Automated Hand Sanitiser Dispenser Holder

Hand sanitisers have become an indispensable weapon in our fight against COVID-19. In October 2020, SIA launched a successful limited-time Restaurant A380 @Changi. For this event, the holders for the automated sanitiser dispensers installed throughout the aircraft cabin were commissioned by SIA to be designed and 3D printed by SIMTech.

30 pieces of lightweight sanitiser dispenser holders were manufactured using 3D Additive Manufacturing technology (utilising SIMTech’s Stratasys Fused Deposition Modeling Fortus 400mc machine) and delivered within an accelerated 1-month turnaround time to support SIA’s high-mix low-volume fabrication demand.

The sanitiser dispenser holder design was modelled and optimised using CAD modelling software (CREO). The CAD Model was subsequently imported into a Finite Element Analysis (FEA) simulation study to evaluate the performance of the 3D printed part using ABS-M30 material to ensure the design was capable of withstanding at least 20kg of abuse load.

Project 2 - Cabin Hand Sanitiser Dispenser Holder Assembly

With the success of the SIA Restaurant A380 @Changi event, SIMTech was consequently engaged to design and fabricate a lightweight aircraft cabin hand sanitiser holder assembly to be installed on the SIA fleet of aircraft. The aim of installing the hand sanitisers on board was to encourage the passengers to sanitise their hands frequently during flight to prevent the transmission of viruses in the confined spaces. This product further strengthens our local aircraft cabin product design and manufacturing value chain under the SIMTech Production Organisation Approval (POA).

The COVID-19 crisis has brought about great opportunities for us to integrate, create and differentiate. We are glad to have this opportunity to collaborate with SIMTech and SIAEC to design, manufacture and install sanitiser holders on board our aircraft, as part of the enhanced health and safety measures that we have embarked on to protect our customers and staff when they fly with us

Mr Sito Wai Seng, Senior Manager, Singapore Airlines

For the cabin hand sanitiser holder assembly project, SIMTech designed, manufactured and assembled 1,150 pieces of lightweight hand sanitiser holders using injection moulding technology. The hand sanitiser holder assembly was optimised using the CAD modelling software (CREO) to ensure that the sanitiser bottle can be secured without strap and is easy to change. A series of Finite Element Analysis (FEA) simulation studies and experimental design verification tests were conducted to ensure that the holders fulfilled the stringent structural and airworthiness requirements (meeting the G-load requirement during aircraft emergency landing condition and capable of withstanding at least 20kg of abuse load). A leather strap was incorporated into the holder assembly as a further safety measure to ensure that the sanitiser bottle remains secured in flight above design loads.

The project involved designing the manufacturing process while maintaining POA protocol. Stringent quality controls were in place to ensure the process chain met the Civil Aviation Authority of Singapore (CAAS) airworthiness requirements with authorised release certificates (ARCs) issued for the parts manufactured.

SIMTech with its own POA accreditation system provided the necessary counsel to develop local Small Medium Enterprises (SMEs) like Dynamold Precision Pte Ltd and Lux Cabin Interior Pte Ltd to form the second-tier supply chain for local aircraft interior component manufacturing.

For enquiries, please contact

Mr Tan Chee Tat, Director, PE COI

Email: cttan@SIMTech.a-star.edu.sg

Web: www.a-star.edu.sg/SIMTech-PECOI

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)