- Press Releases

- Industry Updates

- SIMTech Manufacturing Matters

- Manufacturing Matters

- SIMTech 30th Anniversary

- Events

- ASPEN2022

- BCA Green Mark (Platinum) for Healthier Workplaces and Laboratories

Fight Climate Change Through Energy Profile Optimisation

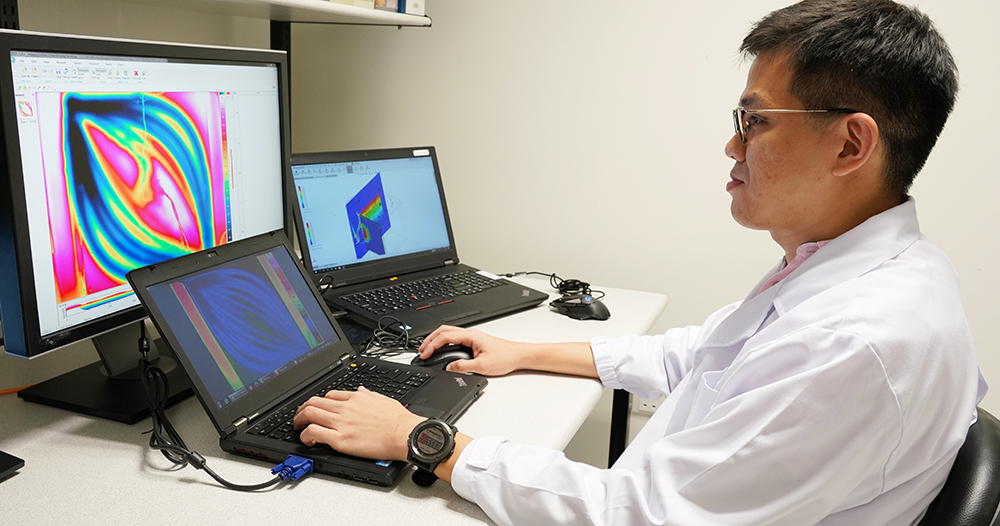

Visualising thermal flow behaviour using simulation for better system design

One of the ways to address climate change is to look at how the manufacturing industry and commercial sectors are utilising energy. It is common for manufacturing and facilities management equipment designers to oversize its capacity to ensure the supplies of resources are sufficient given limited information or a lack of understanding on energy demands. Most of the energy generated are used for heating and cooling purposes, leading to high non-productive energy usages and losses.

There are other ways to improve energy efficiency including

- Using new methods and materials in heating such as three-dimensional induction heating elements versus conventional oil heating. This enables more effective heat transfer management and significantly reduces energy consumption.

- Precision measurements that enable us to understand better on the energy maps to address hotspots and reduce waste heat and non-productive usages.

- Understanding human behaviours and its usage patterns for smarter and accurate control.

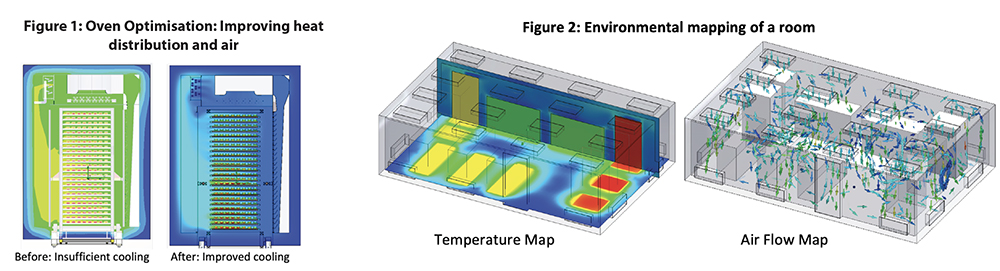

Figures 1 and 2 show the case studies we had worked on to simulate both temperature and airflow to improve energy efficiency within an oven and a room respectively. In the case of a simulation of an oven as shown in Fig 1, the air flow distribution can be studied and improved through strategic placement of ducts and louvres. Subsequently, the requirements for cooling and heating of the air can be approximated for the given loading condition within the oven allowing, new materials to be explored. Various loading conditions can be simulated to determine if the heating and cooling modules are sufficient for the intended conditions. With this information, the oven can be better designed.

In Fig 2, the simulation and analysis of a room is carried out to help identify hot spots and to understand how it would affect the surroundings. The strategic placements of solutions, such as air-conditioning units or fans, to aid in the cooling of the room can then be determined. In addition, the rearrangement of the room layout to better optimise the air flow within can be studied. Different thermal insulating barriers and air vent louvres designs can be proposed. With a proper analysis, a suitable HVAC system can be sized while still ensuring thermal comfort for people working in the room.

Companies can leverage on SIMTech’s capabilities in modelling, simulation and analysis to validate their products and processes design to achieve the common sustainability goals towards a better energy profile. In this way, improving profitability and environmental impact can be achieved hand in hand.

For enquiries, please contact

Dr Ng Sum Huan Gary, Deputy Director, SEAC

Email: shng@SIMTech.a-star.edu.sg

Web: www.a-star.edu.sg/SIMTech-SEAC

![]()

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)