RESEARCH IN SIMTECH

Printed Intelligent Device Group (PIDG)

INTRODUCTION

Conventional sensor electronic circuit fabrication relies on lithography and subtractive processes. The growing need to achieve cost-effective, energy-efficient and environmentally friendly manufacturing is driving a paradigm shift towards large area manufacturing processes, widely known as printed electronics.

PID leverages SIMTech’s interdisciplinary manufacturing technologies and competencies to research, innovate, and commercialise printed electronics manufacturing processes for emerging and use-inspired applications. PID’s key research focuses on disruptive form factor of printed sensors leveraging manufacturing processes such as coating, printing, laser patterning and lamination.

RESEARCH THEMES

- Process Technology

The team focuses on- New formulation of functional ink for Roll-to-Roll manufacturing processes and applications

- Development of large area Roll-to-Roll additive deposition for submicron coating, multilayer coating of Heterogeneous materials, printing and patterning of conductive, dielectric and resistive inks on various types of flexible substrate such as polymer, paper and metal

- Hybrid process integration

- Interconnecting process and materials for soft-hard electronic interfaces

- Application Technology

The team focuses on

- The development of large area devices with functional inks for human-machine interface, flexible lighting

- Development of flexible hybrid printed electronics - stretchable and formable electronics for wearables, Internet of Things, flexible and conformable sensors

- Electronic module design

CORE COMPETENCIES

- Formulation and processing of printable functional materials

- Functional film fabrication, transfer and lamination

- Roll-to-Roll coating and printing

- High-precision Roll-to-Roll web handling

- Flexible hybrid electronics processing and system development

- Laser patterning and thru-polymer-via processing

- Digital dispensing process for device structuring & integration

- Electronic component encapsulation and passivation

TECHNOLOGIES FOR LICENSING AND TRANSFER

- Manufacturing Process for Flexible Electronics

- Sheet-to-Sheet and Roll-to-Roll printing processes

- Thermal transfer of printed devices from polymer to fabric

- Flexible Functional Parts

- Roll-to-Roll printed transparent conductive film

- Printed flexible, conformal sensors, circuitry and devices, e.g. printed heater, ECG electrode, pressure sensor

KEY ACHIEVEMENTS

- Licensing of printed lighting technology

- Licensing of printed heater technology

- Licensing of functional printing technology

- A*STAR Thematic Strategic Research Project: Roll-to-Roll Manufacturing of Printed Electronics

- A*STAR Thematic Strategic Research Project: Multi-Functional Substrate Platform For Smart Sensor With Wireless Interface Applications

LISTING OF SOME MAJOR EQUIPMENT

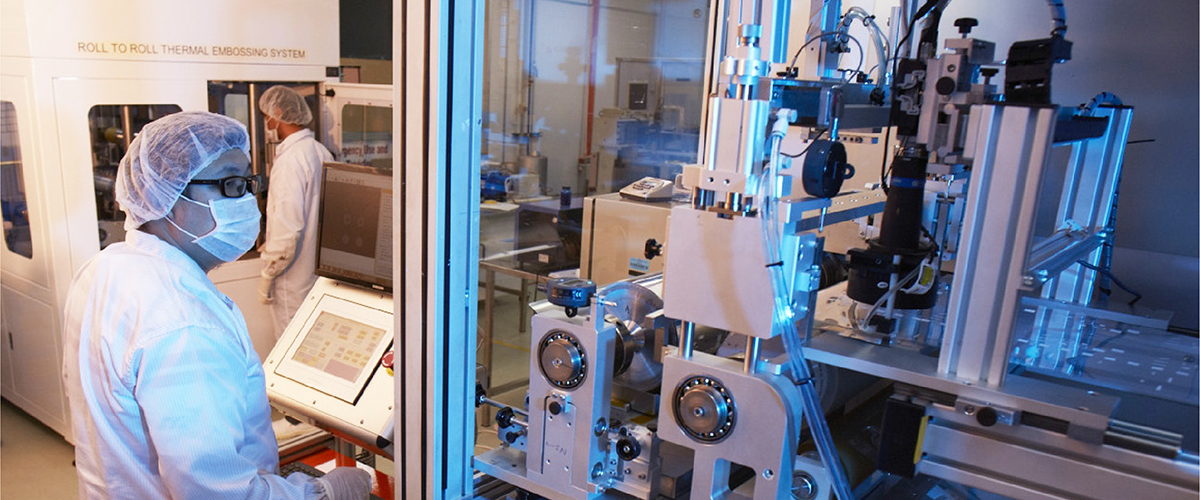

- 800 m² Class 10K Cleanroom

- Roll-to-Roll and modular processing system for large web (web width of 1 metre and 0.3 metre) and pilot scale coating, patterning, embossing and lamination

- Roll-to-Roll embossing system

- Roll-to-Roll coating system

- Roll-to-panel-to-roll screen printing system

- Screen printer

- Ink-jet printer

- Thermal, infra-red, ultraviolet (UV) curing and photonic sintering systems

- Materials and ink development facilities

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)