Learning

Apart from co-innovation and technology transfer, the Model Factory also plays a significant role in helping companies to train their staff to be equipped with the necessary skills to support their digital transformation journey. The hands-on trainings are conducted in an unique, immersive learning environment of the Model Factory, allowing for experiential experimentation and learning

The A*STAR Model Factory at SIMTech is proud to be part of the International Association of Learning Factories.

The Model Factory hosted the 12th Conference on Learning Factories (CLF), an international conference for top academics and researchers in the field of learning factories related to manufacturing engineering and production management, in 2022, the first time the CLF was held outside Europe.

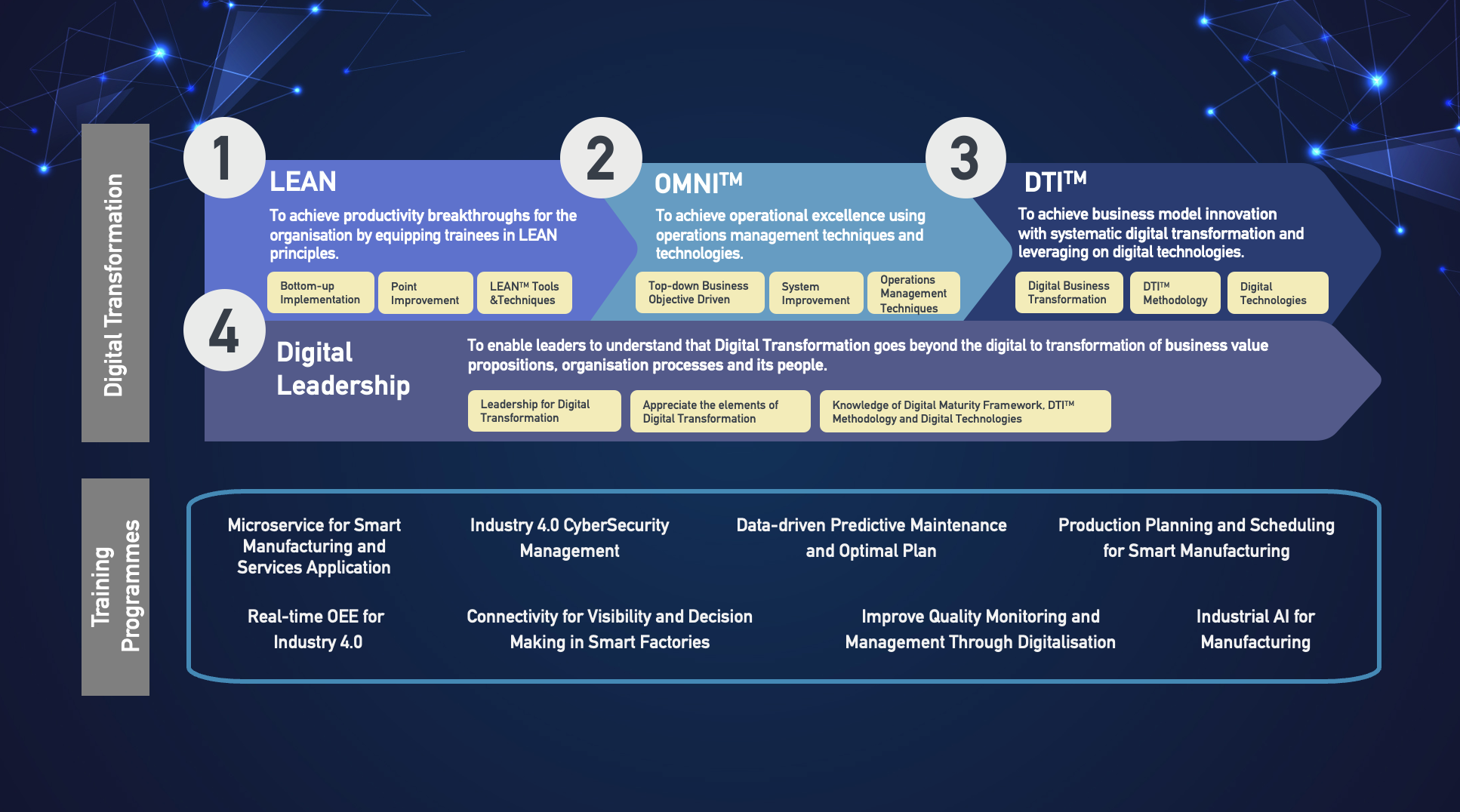

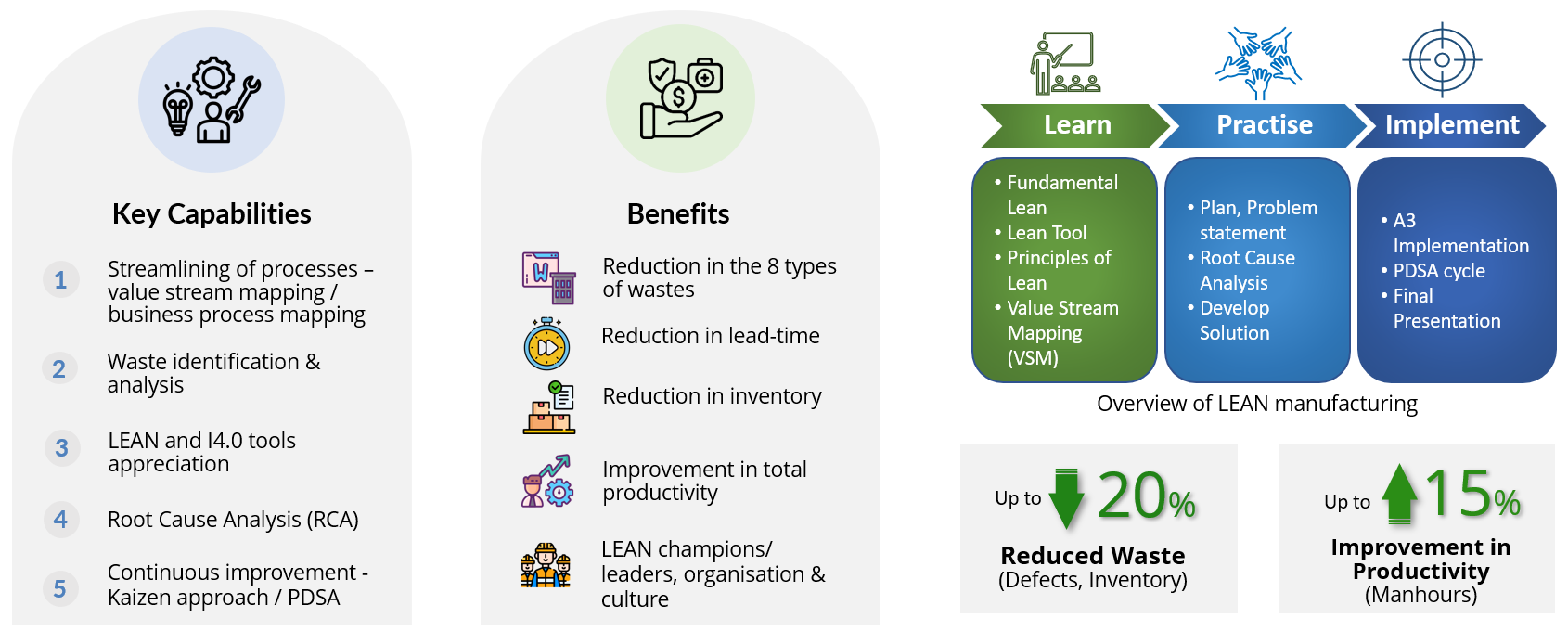

LEAN

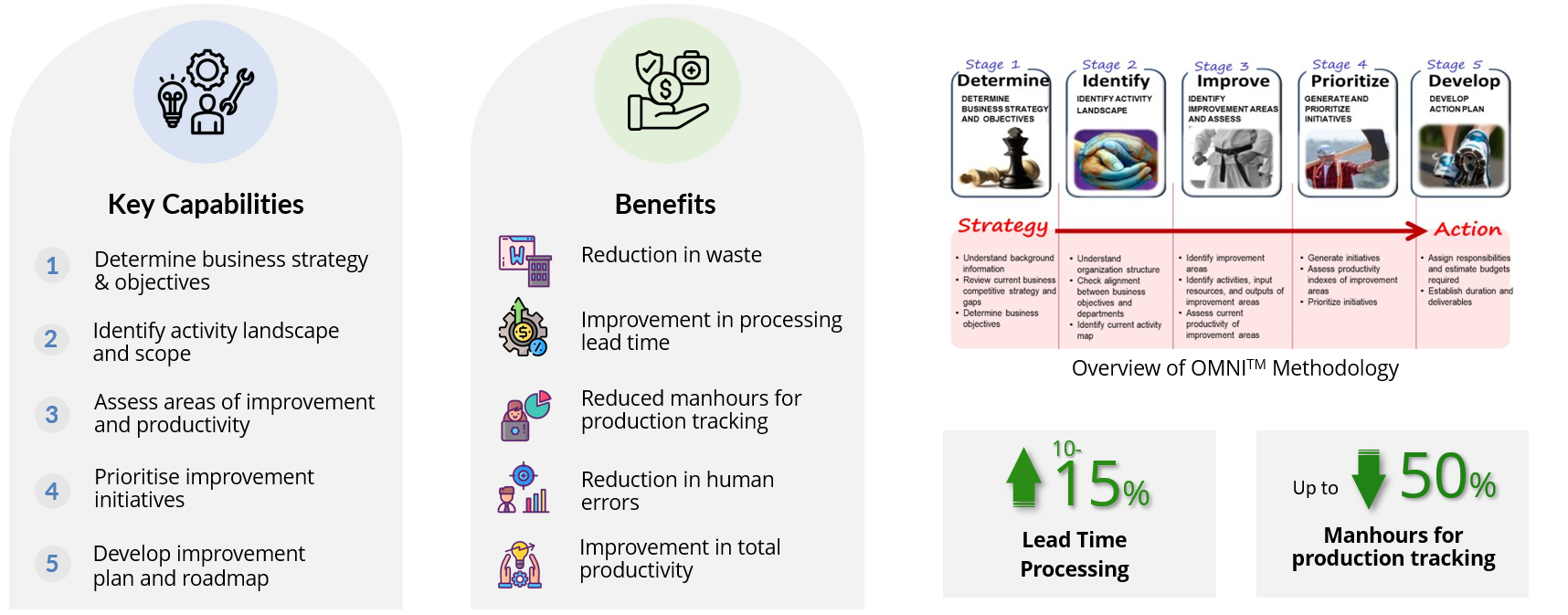

Operations MaNagement Innovation (OMNI)

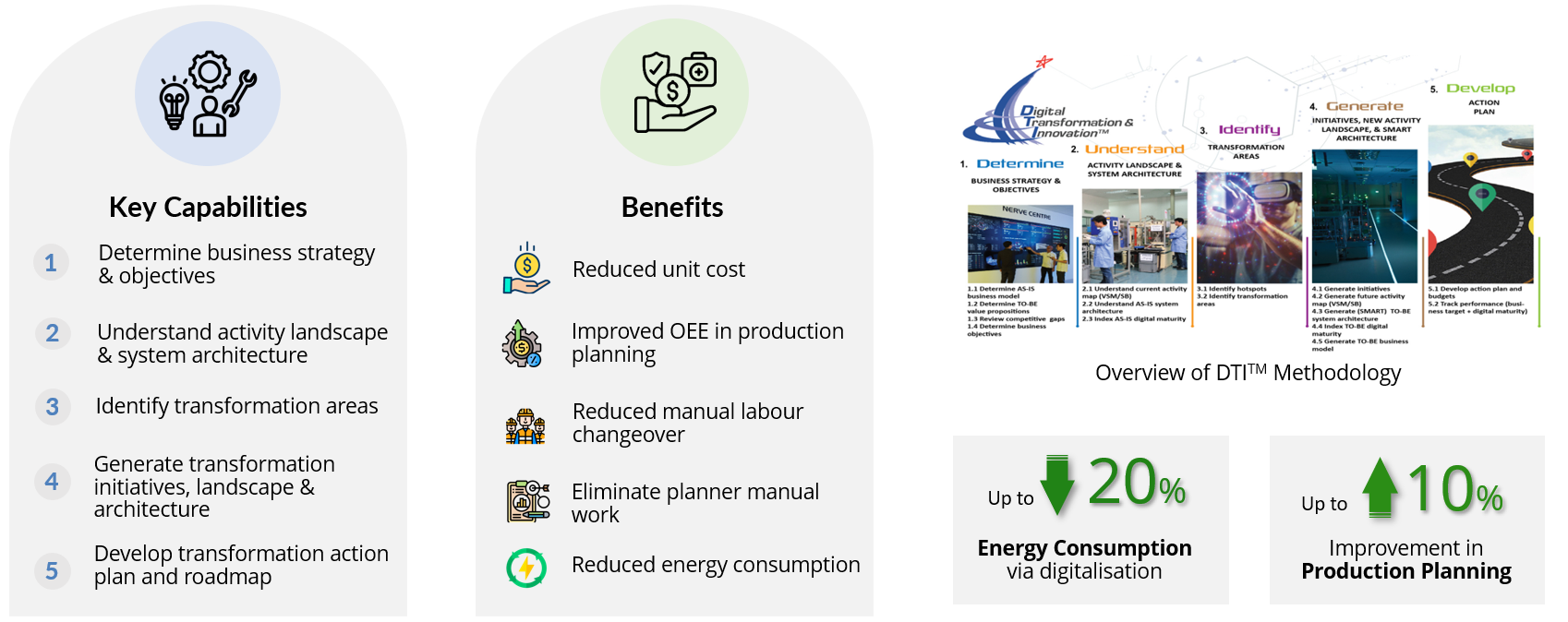

Digital Transformation and Innovation (DTI)

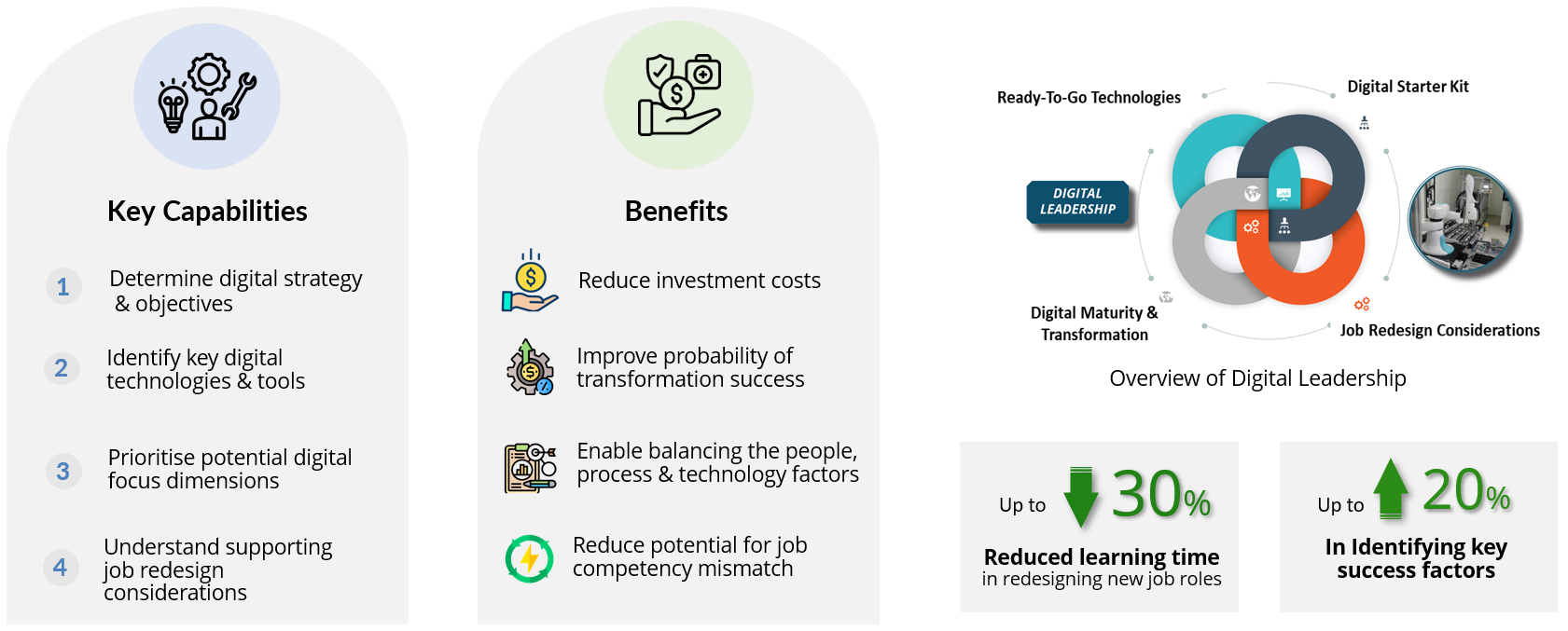

Digital Leadership

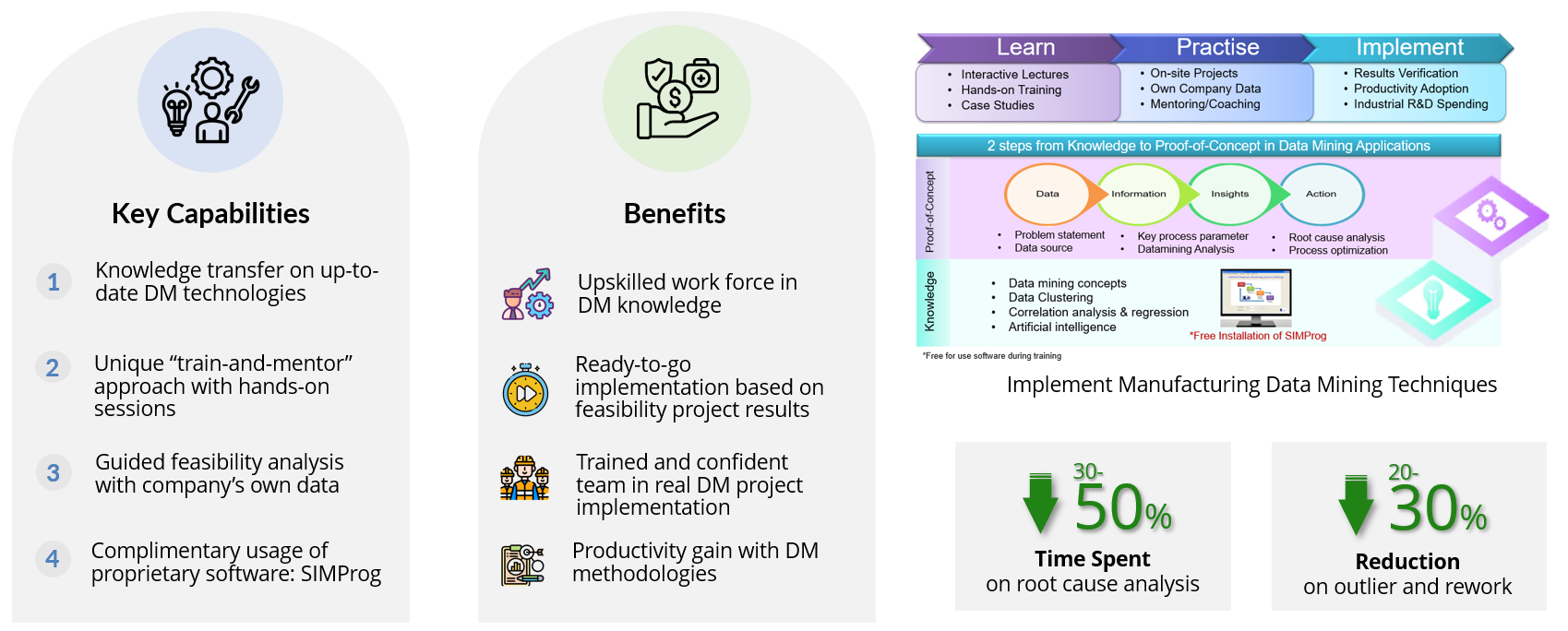

Manufacturing Data Mining

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)