.jpg?sfvrsn=7074fd68_4)

Acoustic MEMS

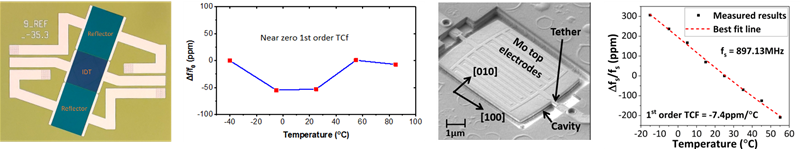

The Acoustic MEMS research group harnesses acoustic waves manipulated on a microfabricated chips for a broad range of applications that include next-generation fast computation, ultrasound imaging and non-destructive testing, gesture recognition, sound generation and perception, wireless power delivery, cell & particle manipulation on lab-on-chips, ultra-low power wake-up sensors for Internet-of-things (IoTs), wireless passive sensors for environmental monitoring, high frequency piezoelectric resonators for ultra-low power wireless communications for IoT.

Infrastructure

IME can provide services in acoustic testing and characterization ranging from kHz to MHz. We have developed a fully automated acoustic mapping setup for characterizing immersion and air-coupled ultrasonic transducers.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM