R&D Foundry

Wafer Fabrication Services

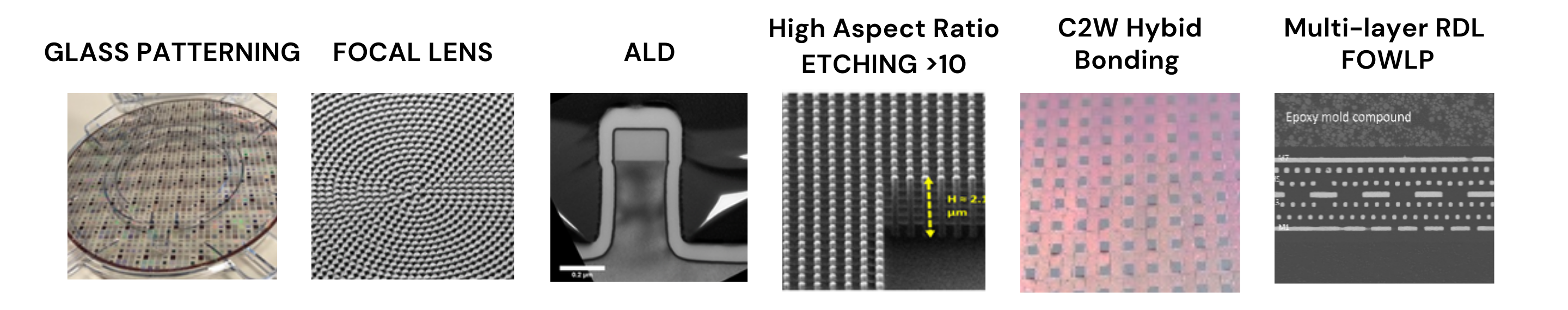

The Institute of Microelectronics (IME) offers a broad range of services to our customers to meet the research and development (R&D) needs of the semiconductor and related industries.

IME’s Fab is located in-house and provides R&D services related to advanced packaging, piezo MEMS, photonics and flat optics, wide bandgap semiconductors, and Medtech applications. IME is equipped with industry-standard 200 mm and 300 mm wafer processing equipment in 3000 m2 of Class-10 cleanroom facilities, supported by metrology, assembly, material characterization and electrical characterization laboratories.

Lithography

- GHI-line Steppers (>0.8 µm L/S)

- ArF Immersion scanner (>45 nm L/S)

Physical Vapor Deposition

- Ta/TaN Cu barrier seed

- Al/ Ti / TiN

Chemical Vapor Deposition/Atomic Layer Deposition

- Cu RDL, Cu pillar, Cu TSV, Cu damascene

- UBM, SnAg bump

Electroplating (ECP)

- Cu RDL, Cu pillar, Cu TSV, Cu damascene

- UBM, SnAg bump

Bonding

- Polymer/glue bonding

- Fusion bonding

- Hybrid bonding

- Metal TCB/Eutectic bonding

Metrology

- Macro & Micro Defect Review

- Defect Review SEM

- Sidewall Roughness

- Surface Morphology

- Film Stress/ Warpage

- Film Thickness measurements

Furnace

- Anneal

- Polymide , Dielectric Cure

Etch

- Desdum

- Silicon

- Oxide

- Silicon-Nitride

Customized Solutions

- Specialty CVD/PVD depositions

- New materials evaluations

Fab Services

Lithography

- 365nm Stepper

- 193nm Immersion Scanner

Physical Vapor Deposition

- Cu

- Al

- Ti / TiN

Atomic Layer Deposition

- HfO2 / HfN

- Al2O3

Chemical Vapor Deposition

- Silicon Nitride

- Silicon Oxide

Bonding

- Temporary / Permanent

- Fusion

- Polymer

- Hybrid

- Metal

Metrology

- Macro & Micro Defect Review and Binning

- Defect review SEM

- Sidewall Roughness

- Surface Morphology

- Film Stress / Warpage

- Thickness Measurements

Electroplating (ECP)

- Cu Pillar, RDL, UBM

- TSV Cu

Furnace

- Anneal

- Polymide, Dielectric Cure

Etch

- Descum

- Silicon

- Oxide

- Silicon-Nitride

- Aluminium

Customized Solutions

- Specialty CVD / PVD Depositions

- New Materials Evaluations

- Deep Machines Learning Applications

Chemical and Mechanical Polish

- Silicon oxide

- Copper

- Titanium

Material, Device, Reliability Analysis (MDRA)

Material Devices and Reliability Analysis (MDRA) has the capabilities and cutting-edge facilities to conduct world-class research and development in semiconductor technology. We provide materials and process characterization, failure analysis, and reliability testing to support our industry partners in wafer fabrication, packaging, assembly, and test.

12" Probe Station

- Automated IV, CV measurements on 12" wafers

FEI Double beam FIB

- Up to 65 nA Ga* beam current under 30KV

- High resolution SEM/STEM imaging (0.6nm at 15KV)

- In-situ TEM sample preparation

FE-SEM

- High resolution SEM imaging with EBSD and EDX analysis (0.8nm at 15KV)

3D X-Ray

- Nondestructive 3D X-Ray imaging

- High spatial resolution to 500nm

Ar Ion Milling/Polisher

- Sample preparation for SEM and optical microscope analysis

CSAM Sonix

- Transducers from 15 KHz to 230MHz for C-Scan/T-Scan analysis

- 12" warped wafer compensation

Thermal Shock Chamber

- Test standard JESD22-A104

- Temperature range (-70°C to 300°C)

Thermal Humidity Chamber

- Test standard JESD22-A101

- Temperature stress: 85°C & relative humidity stress: 85%

ESD Tester

- MM/HBM Test

High temperature storage chamber

- Test standard JESD22-A103

- Temperature storage up to 300°C

Thermal Shock (liquid to liquid)

- Test standard JESD22-A106

- Temperature range (-65°C to 200°C)

FEI TEM (CM200)

- 200KV transmission electron beam analysis (resolution < 0.14nm)

Contact us directly for more information.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM