- Press Releases

- Industry Updates

- SIMTech Manufacturing Matters

- Manufacturing Matters

- SIMTech 30th Anniversary

- Events

- ASPEN2022

- BCA Green Mark (Platinum) for Healthier Workplaces and Laboratories

Digitalisation Improves Productivity

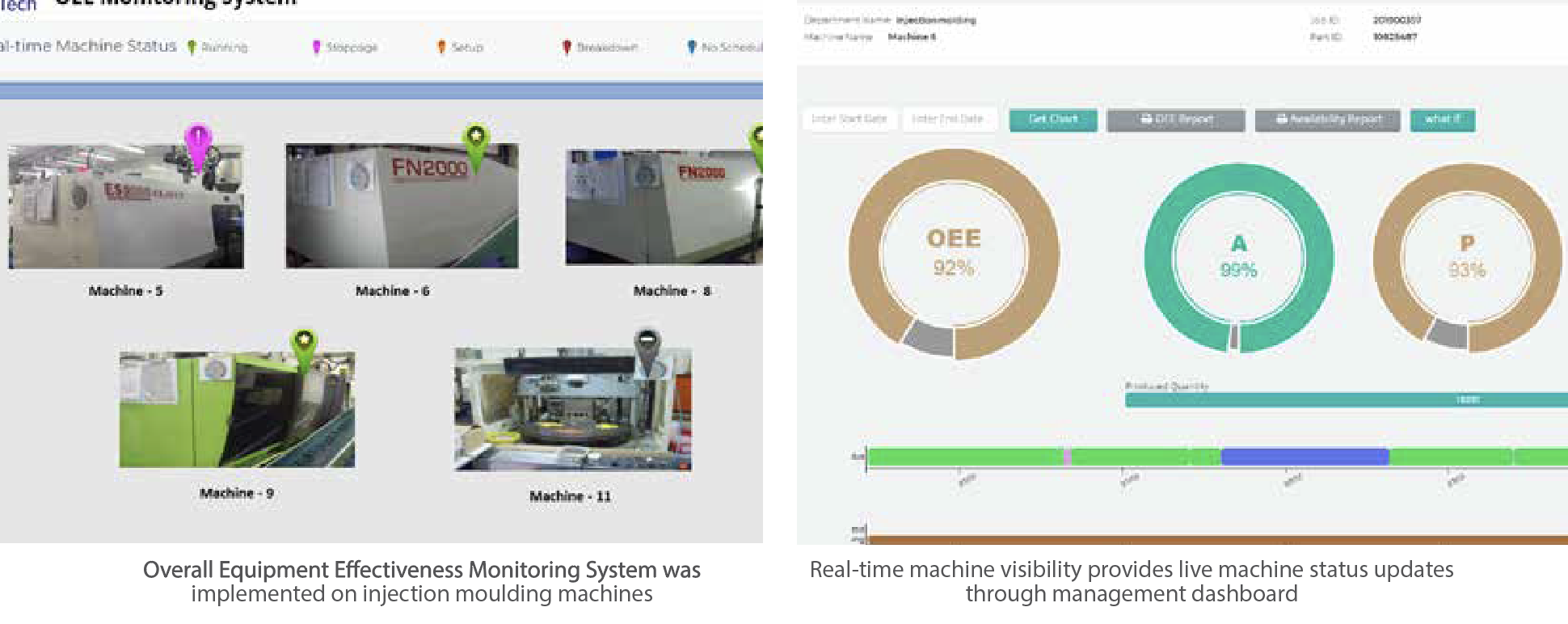

Racer Technology implemented Overall Equipment Effectiveness Monitoring System, Manufacturing Operations Management and Mobile Workflow for shopfloor productivity

To digitalise its operation, Racer Technology Pte Ltd, a medtech contract manufacturer, adopted a suite of technology and system from SIMTech. Previously, Racer used a paper-based method to keep track of its machine operations. However, this manual method is time-consuming, prone to human error and not ideal for data collection and analysis to improve productivity.

To address this, Racer implemented the Overall Equipment Effectiveness Monitoring System (OEEMS) on its injection moulding machines to provide real-time machine visibility. The OEEMS provides live machine status updates through the dashboard, automatically capturing data on machine stoppages, analyse the cause and duration for each stoppage. With this, Racer can now develop effective measures to reduce machine downtime and maximise machine utilisation. OEEMS improves machine utilisation by between 7 to 17 per cent and increase yield ranging from 19 to 21 per cent. Mould set-up time was reduced 39 to 63 per cent through optimised set-up procedure.

SIMTech also implemented the Manufacturing Operations Management (MOM) solution, an integrated production planning and shopfloor tracking solution with raw material management, finished good management, delivery order generation and mobile shopfloor tracking for shopfloor productivity. Training on Manufacturing Operations Management system was also provided.

With this system in place, Racer reduced 75 per cent in report generation time; improved 69 per cent in data capture and production planning time and improved 75 per cent in shopfloor visibility.

SIMTech wfMOBILE™ Technology was applied for quality inspection and inprocess quality control. The manual forms for these were converted to electronic forms for data capture for the sampling process, and reports are automated.

With the digital entry of quality data, the time taken to complete a quality data input is within 30 minutes versus previously unknown cycletime. The estimated paper reduction is 50 per cent. The time taken to search for quality report is reduced from more than 30 minutes to 1 minute.

To enable its employees to use the digitalised technology and systems, Racer also sent 15 of its employees for Workforce Skills Qualifications (WSQ) courses conducted by SIMTech.

The collaborations with SIMTech helped Racer Technology to save on labour costs and improve efficiency in digitalisation. Its factory is able to produce the same output with fewer work shifts

Mr Willy Koh, Chief Executive Officer, Racer Technology

For enquiries, please contact

Dr Tan Puay Siew, Director, MPTC

Email: pstan@SIMTech.a-star.edu.sg

Web: https://www.a-star.edu.sg/simtech/MPTC

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)