SUCCESS STORIES

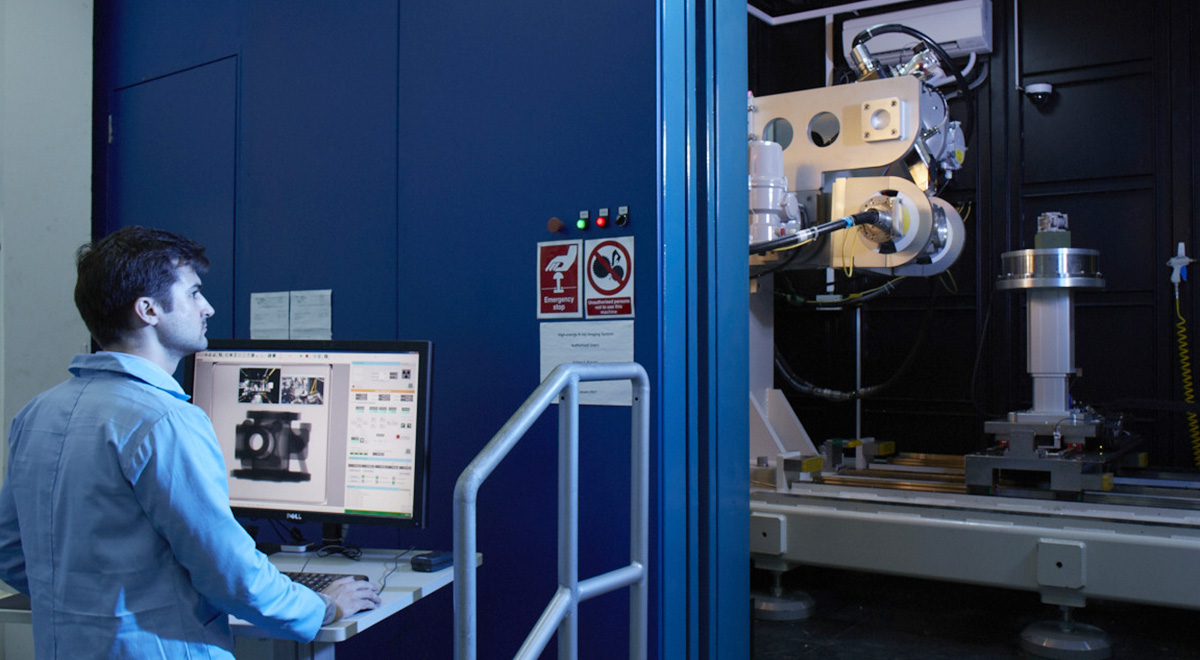

Housing Inspection with High-Energy 3d X-Ray Computed Tomography System

Finding the right tool through Tech Access

Specialising in manufacturing insert mouldings for automotive safety sensors components, Sanwa-Intec (Asia) Pte Ltd had to identify a possible void or leak path during the early stage of a project which involved Computed Tomography (CT) scan of housing component for airbag sensor component.

However, Sanwa-Intec (Asia) faced a problem – conventional 2D scans could only visualise the internal features by slicing from one perspective. As such, the engineers were unable to identify the exact location of the voids within the plastic housing.

In order to view the internal features of the plastic housing, Sanwa-Intec (Asia) worked with SIMTech through Tech Access to access the High-Energy 3D X-Ray Computed Tomography System (HECT) to perform non-destructive scanning of plastic housing samples.

Not only for new projects, 3D X-Ray CT scans are useful in some continuous improvement programmes that require the study of internal features

Ms Hla Myint Zu, Customer Quality Engineer, Sanwa-Intec (Asia) Pte Ltd

The HECT system was used to scan each sample from different orientations to produce 3D X-Ray CT images. The 3D X-Ray CT scans show the location and size of voids on the internal portion of the plastic housing sample. Engineers from Sanwa-Intec (Asia) were able to use these internal images to locate the voids / leak path inside the housing.

Based on the results, Sanwa-Intec’s engineers were able to rectify the issue, improve the quality and design of their product.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)