Sustainable Operations

Resource Efficiency to mitigate scope 2 and/or 3 emissions by reducing energy, material and water consumption and wastage

Technology

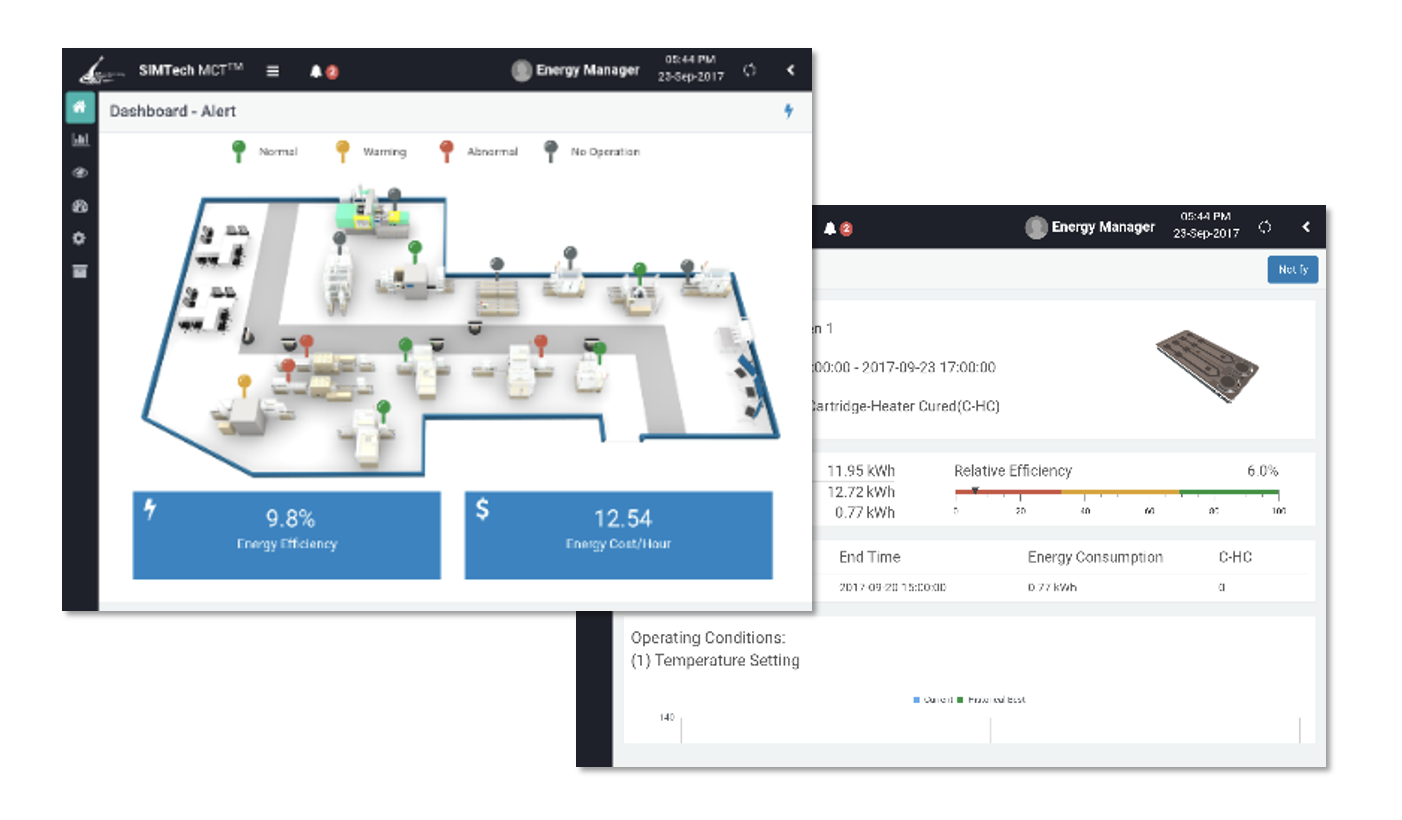

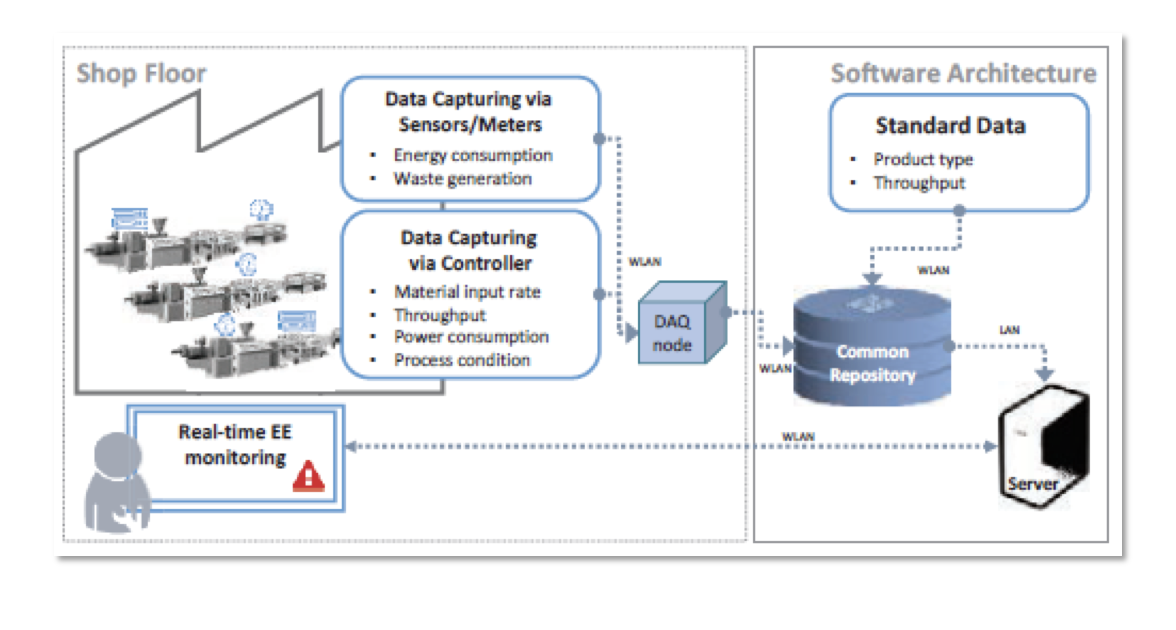

Deployment of E2MAS at LHT Holdings Limited

close

Improving manufacturing equipment energy efficiency in timber industry

Power meters have been installed at the pallet assembly and polishing machines. Energy anomalies are detected while energy efficiency gaps are quantified.

Hotspot analysis allows LHT to understand day-to-day energy usage of its manufacturing processes and embed best practices in energy management.

As a mobile application, E2MAS shows the real-time capability of energy efficiency monitoring and analysis. Reference days with the respective operating conditions are provided as guidance on achieving the best.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)