Apply Surface Enhancement And Finishing Technologies (42 Hours)

Introduction

Most components used in many industries such as aerospace, automotive, marine, or energy are subjected to heavy and demanding operating conditions. As such, these components need to be enhanced to achieve the desired functional performance, aesthetics and high fatigue life. These value-added enhancements can be realised through a myriad of surface enhancements and finishing technologies. It is thus important to understand the fundamentals and principles of these technologies, in particular, state-of-the-art mechanical and laser techniques and how these processes react with materials to better optimise the process efficiency, product quality and cost to maximise the economic benefits for businesses.

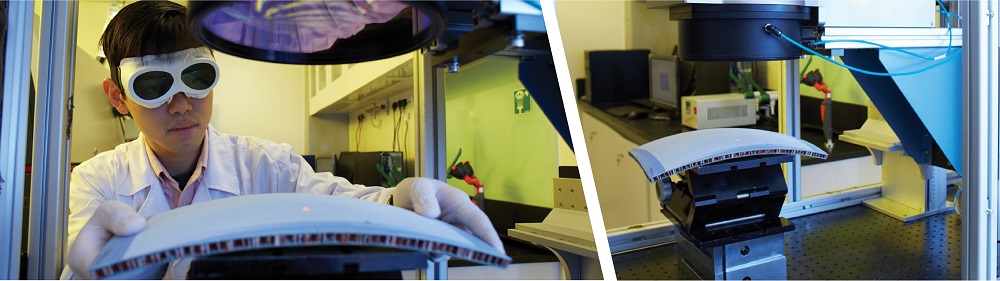

This module introduces the fundamentals of surface enhancement and finishing processes via mechanical and laser techniques, such as rolling, peening, burnishing, mechanical finishing processes (eg. vibratory bowl finishing), drag finishing, abrasive flow machining, magneto-rheological finishing and grinding, laser surface treatment for functionalities and marking, laser peening and laser finishing processes. Participants will gain a solid understanding of these processes and the issues and effects on work substrates. Participants will also be guided through hands-on project-based sessions on real-world industrial topics using SIMTech equipment and instruments to further enhance their understanding of surface enhancement and finishing technologies and applications in the manufacturing industry.

Why This Course

- Highly practical and intensive

- Latest knowledge and up-to-date technology

- Case studies highlighting industrial application

- Expert trainers in the field with industrial experience

Who Should Attend

This course is designed for engineers, researchers and technicians from the precision engineering, electronics, aerospace, automotive and other relevant industrial sectors.

About our Trainer

Dr Wang Xincai

- For technical enquiries, please contact:

Dr WANG Xincai,

Email: wang_xincai@a-star.edu.sg

Contact Us

Registration

- Please register for this course through our online form: Course Registration Form for Public Classes.

- For the first question, please select "Modular Programmes (Standalone Modules)".

- Applicants will be placed on our waiting list if the course does not have an upcoming scheduled intake.

- When the next intake is confirmed, a confirmation email with payment information will be sent to applicants to finalise their participation.

Schedule

Note: A*STAR SIMTech and A*STAR ARTC reserve the right to change the class/schedule/course fee or any details about the course without prior notice to the participants.

Announcement:

- From 1 Oct 2023, attendance-taking for SkillsFuture Singapore (SSG)'s funded courses must be done digitally via the Singpass App. More information may be viewed here.

- Participants will be provided with digital course materials when attending our courses. Please note that printed copies will not be available.

: Full day

: Full day : Morning

: Morning : Afternoon

: Afternoon : Evening

: EveningQuick Link

- View the full list of modular programmes offered by A*STAR SIMTech and A*STAR ARTC.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)