Overall Equipment Effectiveness

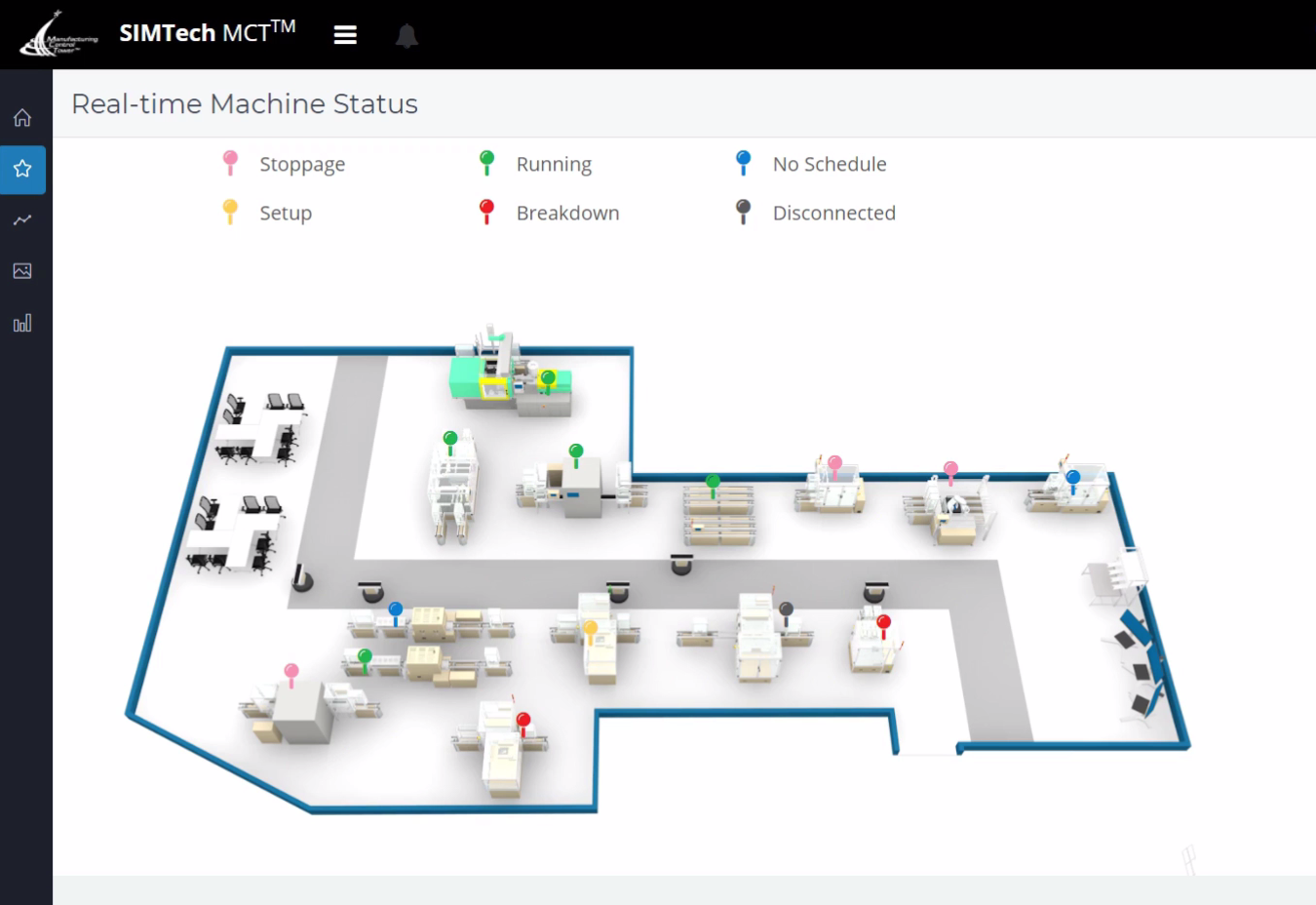

Real-time OEE Monitoring provides an overview of the machine status. It also provides an overview of real time OEE calculations. The OEE report provides details for root cause analysis, while availability comparison shows the utilisation between machines. Users can analyse OEE trends based on different time periods and find out the best and worst performers of the machines in the OEE summary.

To download the brochure, please click here.

Machine Utilization Data Acquisition (MUDAQ)

Machine Utilization Data Acquisition (MUDAQ) is developed by SIMTech. It has the ability to interface with controllers or legacy machines using both sensors and Human Machine Interface (HMI) technology. Job details are captured, together with the duration of setup taken. The sensor installed automatically detects machine running or stopping and pops out a reason code for selection. With a single touch, the downtime is recorded and sent to the OEE monitoring system in real time. The quantity amount is recorded when the job has been completed. Multi-lingual can also be programmed.

Real-Time OEE Monitoring

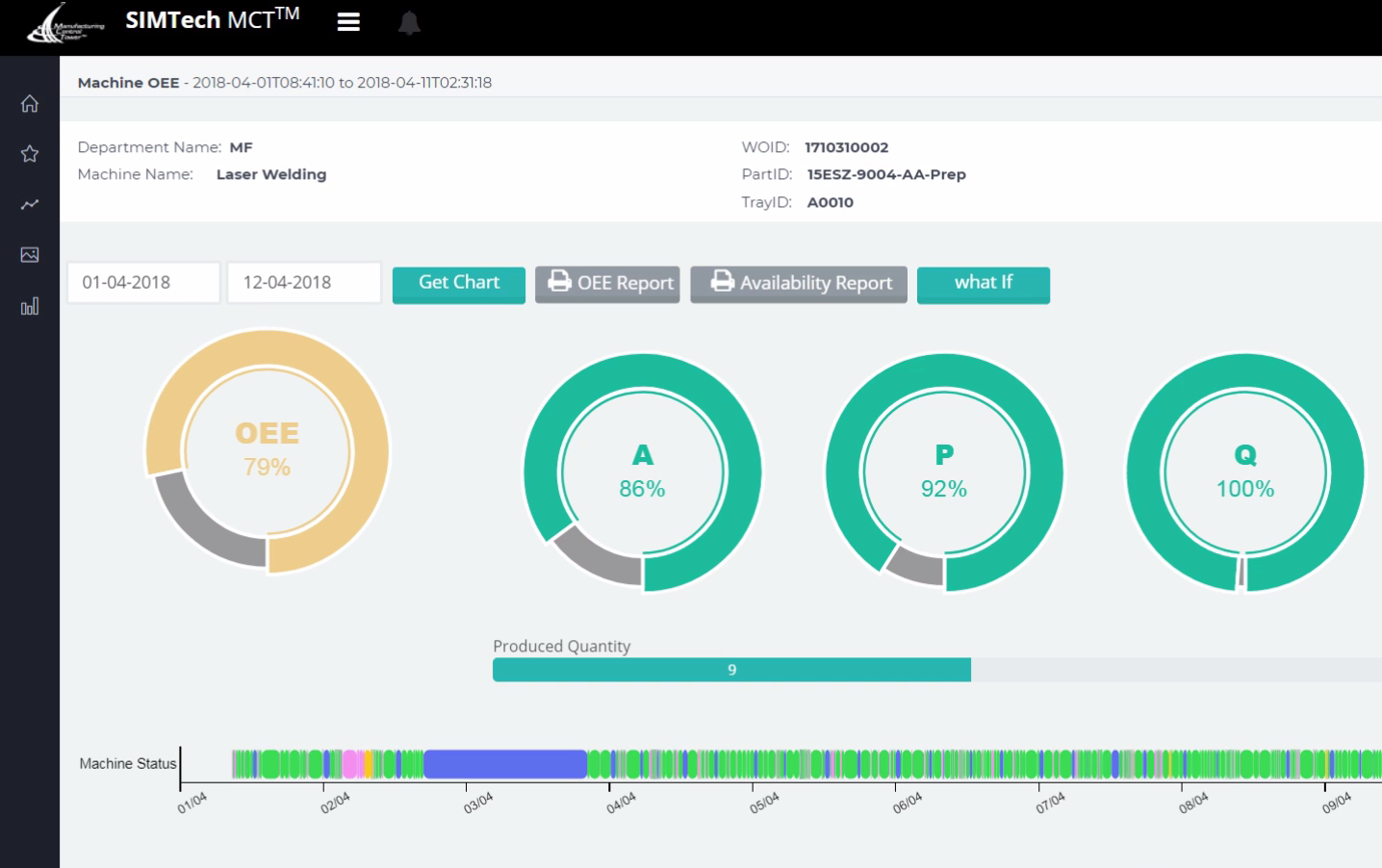

Real-time OEE Monitoring provides an overview of the machine status. It also provides an overview of real-time OEE calculations. Drilling into individual machine OEE analysis provides availability, performance, quality, OEE score, job execution details as well as historical machine events with start and end times. Machine status summary can be seen at a glance.

Root Cause Analysis

An OEE report can be generated for root-cause analysis. Reasons are sorted to pinpoint top key losses. It provides an actual machining time vs standard machining time comparison and calculates the loss in machine efficiency. The setup efficiency of actual setup time vs. standard setup time can also be analysed. The user could use the What-If analysis to simulate improvement areas and impacts, while justifying the investment needed with the return on investment (ROI) feature. This simulation is extremely useful before any real-life implementation. What-If analysis reports can also be generated.

OEE Comparison

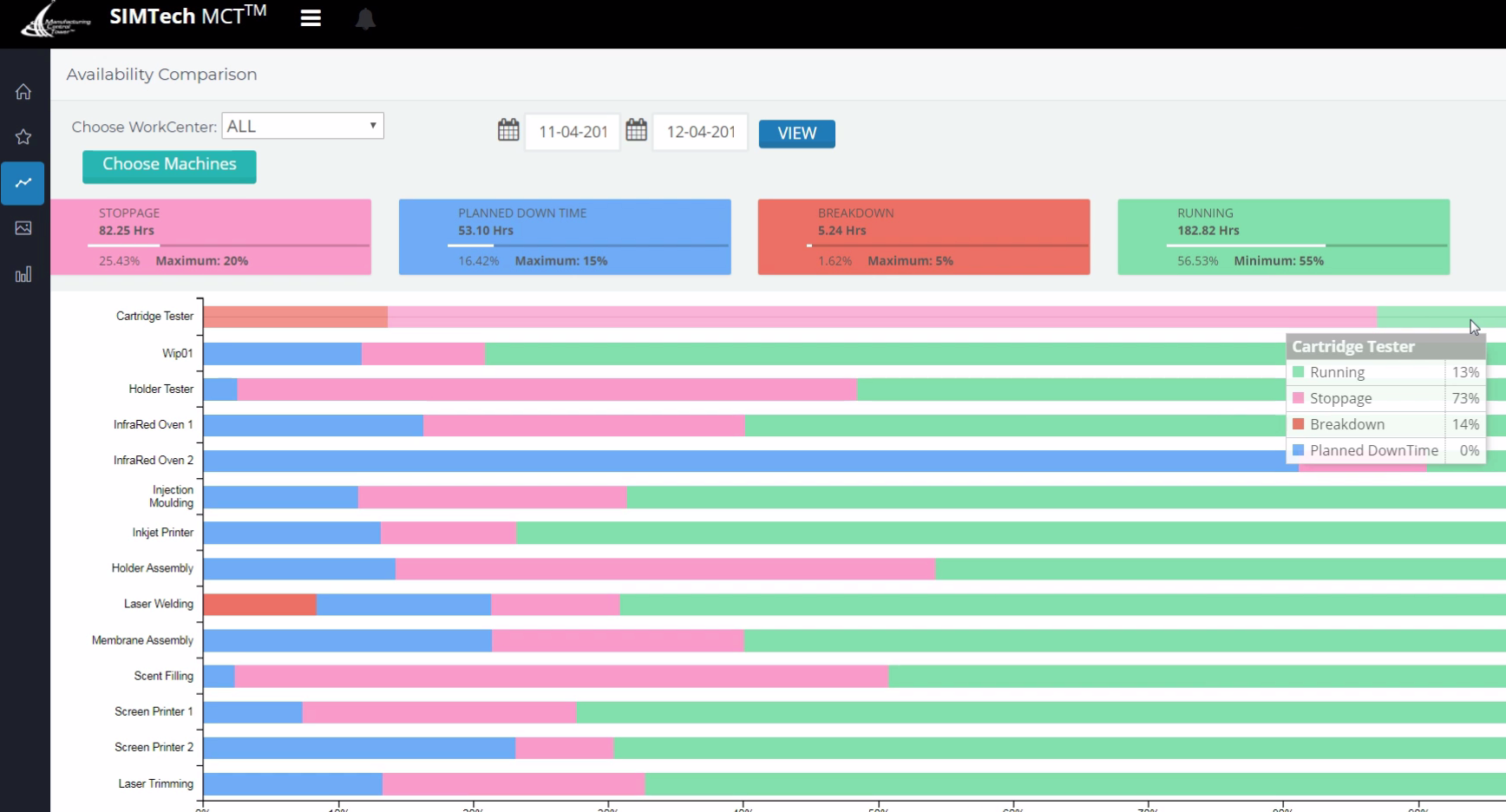

Availability comparison compares the utilisation between machines in the department or factory with easy to understand colour codes that provides a good visualisation of the machine that needs attention. The user can analyse OEE trends based on different time periods to implement corrective actions when necessary and find out the best and worst performers of the machines in the OEE summary.

Dr Zhou Junhong

Principal Research Engineer

☎ : 6510 1626 | ✉: jzhou@SIMTech.a-star.edu.sg

Mr Wong Ming Mao

Deputy Director, Manufacturing Productivity Technology Centre

☎ : 6510 1690 | ✉: mmwong@SIMTech.a-star.edu.sg

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)