RESEARCH IN SIMTECH

Advanced Imaging and Machine-vision Group (AIMG)

INTRODUCTION

Intelligent inspection has gained importance in advanced manufacturing and biomedical diagnostics applications. With this comes challenges in automated optical inspection and deep learning techniques which include the availability of training samples, visibility of key features, and resolution of the optical system. At the same time, large objects and in-situ measurements require imaging instruments to meet new demands in processing speed.

In AIM, we are a one-stop solution provider of automated optical inspection focusing on cutting-edge advanced imaging technologies, including multi-scale imaging, hyperspectral imaging, active imaging and penetrative imaging. Our researchers carry out collaborative research with academic institutions, co-develop equipment and devices with companies, and provide technical services and training to the manufacturing industry.

RESEARCH THEMES

- Optics

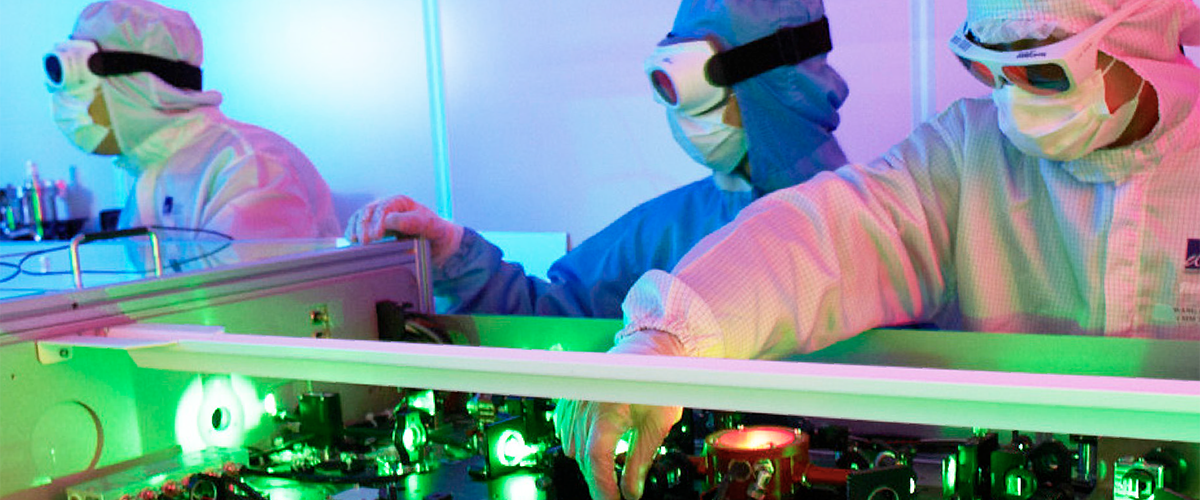

The Optics Team focuses on research and development of high-resolution optical systems for imaging surface and sub-surface features. It involves innovations in ultrafast lasers, optics design, lighting design, optical measurement/characterisation, optical signal detection and optical system instrumentation. The optics team's established core competencies are in visible, mid-IR and X-ray optics. The team is currently developing coherent X-ray source to achieve nanoscale resolution in the X-ray regime. This drives the research in the areas of high power mid-IR laser optics, high harmonic coherent X-ray generation, X-ray imaging, and laser-electron simulation and modelling. - Image Processing

The Image Processing Team focuses on research and development of image processing technologies for 2D and 3D automated surface and sub-surface inspection and measurements. It involves innovations in computed tomography (CT) image reconstruction and image processing algorithm. The established core competences of high precision CT for inspection, measurement and high speed 3D image processing. The development drives the research in the areas of 3D fast CT reconstruction methods, 2D and 3D image processing methods, low contrast image features extraction, high dual-energy X-ray CT systems and high-speed image processing for automated inspection.

CORE COMPETENCIES

- Optics and Lighting System Development

- X-ray System and Application Development

- In-line Machine Vision Inspection Solutions

- Laser Optics

TECHNOLOGIES FOR LICENSING AND TRANSFER

- 3D Optical Measurements

- Scanning white-light interferometry for profile measurements

- 3D wire-bond inspection system

- Moiré fringe technique for 3D measurements

- Wavefront sensing for inspection aspherical lens measurement

- Nano-metric Measurements

- Scanning Near-field Optical Microscopy (SNOM)

- Scanning Near-field Photon Emission Microscopy (SNPEM)

- X-ray Inspection

- X-ray Computerised Tomography (CT) and visualisation

- X-ray CT for multi-layered object

- X-ray sterilisation for food packaging and medical device

- X-ray phase contrast imaging

- Vision Inspection

- Glass inclusion inspection

- Wafer surface inspection

- Lens surface defect inspection

- Solar cell defects inspection

- Stem cell culture monitoring system

KEY ACHIEVEMENTS

- The A*STAR Award for Leading, Educating & Nurturing Talent for X-ray Photonics Research Program, 2017

- Institute of Engineers Singapore (IES) Prestigious Engineering Achievement Award for High Power Mid-IR Fiber Laser, 2017

- SIMTech Best Research Award for Towards Graphene Plasmon-based Free-Electron Infrared to X-ray Sources, 2016

- SIMTech Best Research Project Award for Mid-IR Random Laser, 2014

- SIMTech Best Research Project Award for Surface Plamson Polariton in Microstructured Optical Fibre, 2013

LISTING OF SOME MAJOR EQUIPMENT/SOFTWARE

- Optics

- Zemax

- Optikos MTF measurement Instrument

- Image Processing

- High energy X-ray CT

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)