RESEARCH IN SIMTECH

Metal & Ceramic Forming Group (MCG)

INTRODUCTION

Metal and Ceramic Forming Group (MCG) focuses on developing various processes to produce near net shape products of metals, ceramics and composites using various technologies and equipment. Industry partners can collaborate with MCG to develop new components or improve existing products by employing state-of-the-art material processing technologies and simulation techniques.

The group collaborates with industry partners and academia to work on cutting-edge research, develop new solutions through projects and joint labs, transfer technology and conduct training for the manufacturing industry.

RESEARCH THEMES

- Incremental Metal Forming

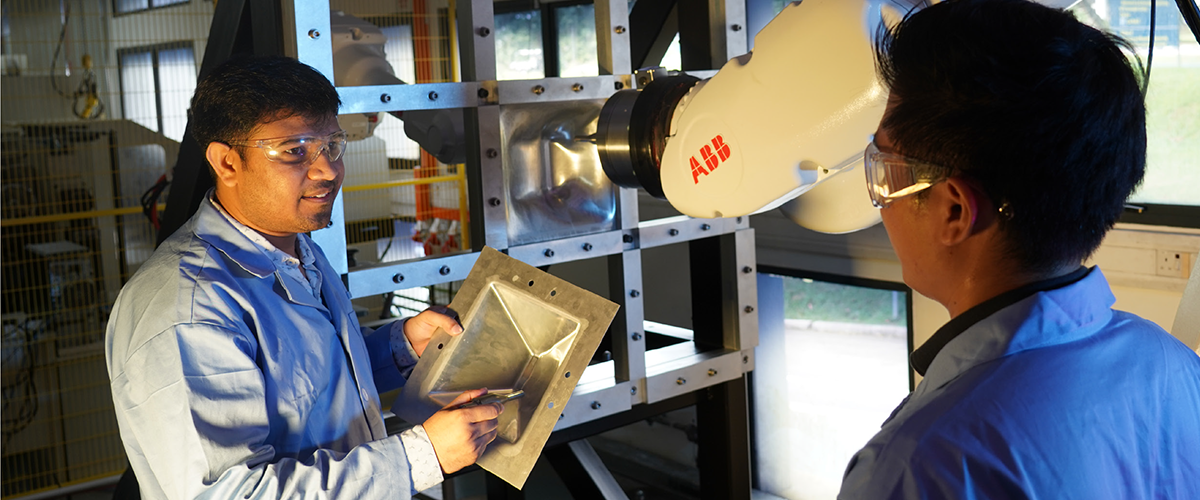

MCG has vast experience in manufacturing technologies of components from metals. This team specialises in new development in CNC and robotic die-less sheet forming, forming of innovative free-form honeycomb structures, combined stamping-forging, advanced spin forming, and hybrid extrusion of bi-metals. - 3D Additive Manufacturing

MCG is at the forefront of 3D printing technologies to produce metal, ceramic and composite components, including functionally graded structures, for high-value industrial applications. The team has expertise in (i) design, modelling and simulation, (ii) feedstock / binder development, (iii) powder-bed fusion, jetting technologies and (iv) AM system / hardware development. - Hybrid Metal & Ceramic Composite Processing

MCG focuses on the development of hybrid composite processes to create dimensionally accurate parts with superior mechanical strength and multifunctional properties, while optimising cost-benefits. The team specialises in Powder Injection Moulding (PIM), micro PIM, PIM overmoulding of complex structures with internal features/channels, powder extrusion of metals and ceramics, and Liquid Forging (LF) of Al, Mg and metal matrix composites.

CORE COMPETENCIES

- Hybrid Metal and Ceramic Composite Processing:

- Hybrid powder forming and gel casting of large dense and porous metal and ceramic components

- Liquid forging of light alloys and metal matrix composites

- Incremental Metal Forming:

- Die-less forming of large free-form sheet metal parts

- Forming of novel free-from honeycomb sandwich structures

- Thermo-Mechanical Processing (TMP) for lightweight components with enhanced mechanical properties

- Simulation and Characterisation:

- Material characterisation and component analysis

- Processing design and optimisation through advanced simulation

TECHNOLOGIES FOR LICENSING AND TRANSFER

- Hybrid Metal and Ceramic Composite Processing

- Liquid forging of Aluminium (Al), Magnesium (Mg) alloys and composites

- Powder Injection Moulding (PIM) and micro PIM of stainless steel, titanium and alloys, nickel super alloy, tungsten carbide, zirconia, and refractory ceramic

- PIM overmoulding of complex structures with internal features/channels

- Gel casting of large format components

- Incremental Metal Forming

- Robotic die-less sheet metal forming

- Advanced spin forming of light alloys

- Combined stamping forging and tailor-formed blank of Al alloys

- Hybrid extrusion of bi-metals

KEY ACHIEVEMENTS AND MAJOR PUBLIC-PRIVATE FUNDED ACTIVITIES

- Licensing of Liquid Forging technology: Aavid Thermalloy in 2012 and Meisterform in 2018

- Industry Joint Lab on Additive Manufacturing Technologies: Applied Materials, Hitachi Metals

- Industry Alignment Fund projects: Polymer Composite Materials Programme (PCMP), Light Weight Programme, Structural Metal Alloys Programme (SMAP), Additive Manufacturing Centre (AMC) Initiative

- SERC Strategic Funding: Lightweight Structures and Functional Coatings for Aviation Products and Applications

LISTING OF SOME MAJOR EQUIPMENT

- Incremental Metal Forming

- 100t Servo Mechanical press

- Robotic die-less incremental forming system

- Spin forming machine

- 3D Additive Manufacturing

- Selective Laser Melting systems

- Electron Beam Melting system

- Selective Laser Sintering system

- Binder Jetting systems

- Powder gas atomiser

- Hybrid Metal and Ceramic Composite Processing

- 200t and 400t Liquid Forging system with robotised ladling and melt metering

- Double-barrel metal and ceramic powder injection moulding machine

- Powder extrusion via injection moulding machine

- Freeze casting machine

- Heat treatment and environmentally controlled furnaces

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)