RESEARCH IN SIMTECH

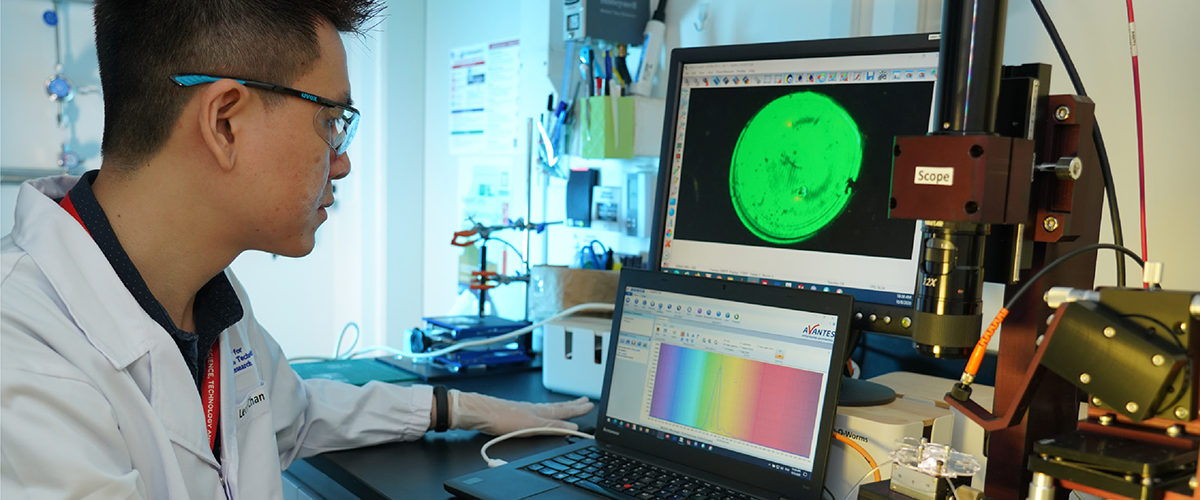

Smart Microfluidics Group (SMFG)

INTRODUCTION

The Smart Microfluidics (SMF) innovates in polymer microfluidics manufacturing to create value from emerging applications. SMF welcomes industry partners and industry-minded academia keen to explore opportunities with us in point-of-care and clinical diagnostics, bio-lab automation, pharmaceutical and life science research as well as food science. By tapping on a developed pool of technologies and harnessing SIMTech’s cross-cutting capabilities, SMF offers comprehensive solutions in microfluidics design and manufacturing.

RESEARCH THEMES

- Microfluidics Applications

SMF has the expertise in miniaturisation of fluid handling systems and precise control of small fluid volumes. Harnessing the potential of microfluidics technology, complex and labour-intensive laboratory procedures are able to be carried out automatically on a chip. Some of our research applications are listed below:

- Point-of-Care and Clinical Diagnostics

- Bio-lab Automation with Lab on a Chip Tools

- Pharmaceutical and Life Science Research

- Food Science

- Microfluidics Chip Manufacturing Processes

SMF’s manufacturing capabilities span the complete microfluidics manufacturing process from structuring, bonding, metallisation, surface treatment to system integration. Our SIMTech Microfluidics Foundry houses a microfabrication line with robust processes to ensure unparalleled quality and value.

CORE COMPETENCIES

As a solution provider for microfluidics manufacturing, SMF offers:

- Design, prototyping and production services of microfluidic devices

- Design/Development and prototyping of microfluidic devices certified by ISO 13485 Quality Management System

- Development of microfluidic devices and systems for various applications including point-of-care diagnostics, bio-pharmaceutical, biomedical research, food and water testing

TECHNOLOGIES FOR LICENSING AND TRANSFER

- Point-of-Care and Clinical Diagnostics

- Point of Care Testing (POCT) System with fully enclosed chips for rapid diagnosis of life-critical bio-markers

- Molecular Diagnosis System with integrated sample preparation, signal amplification and detection

- Bio-lab Automation with Lab on a Chip Tools

- Automatic molecular profiling station

- Circulating Tumour Cell (CTC) screening for rare cell detection

- Automatic Microvesicle (Exosome) Enrichment system

- Pharmaceutical and Life Science Research

- In-vitro skin testing using multi chamber microfluidic system

- GMP & EUP certified micro-encapsulation system for bio-pharmaceuticals

- Food Science

- GMP certified micro-encapsulation system for Probiotics protection & Taste masking

- Hologram Spore Detection system for quarantine and quality control

KEY ACHIEVEMENTS

- Opening of the SIMTech Microfluidics Foundry (SMF) with a microfabrication line spanning the complete microfluidics manufacturing process

- Certified ISO13485 compliant in microfluidics design and development

- Successfully licensed our GMP & EUP certified droplet generator for micro-encapsulation system of bio-pharmaceuticals

- Launch of training courses for industry - “Understand the Microfluidics Manufacturing Processes”, “Lab-on-a-Chip” and “Microfluidics Fabrication”

- Successfully transferred our Lab-on-a-chip product for molecular diagnosis to industry

- Enhanced the capability of a local leading medical device contract manufacturer through transfer of key microfluidics manufacturing technologies

LISTING OF SOME MAJOR EQUIPMENT

- Microfluidics Applications

- Industrial Microscopes (Olympus measuring microscope, Olympus stereo microscope)

- Bioanalytical Equipment (Bio-Rad real-time PCR detection system, Thermo Fisher Scientific NanoDrop spectrophotometer, Bio-rad molecular imager)

- Life Science Equipment (Biofrontier shaking incubator)

- Electronics Equipment (Tektronic mixed signal oscilloscope, Agilent function generator)

- Microfluidics Chip Manufacturing Processes

- Chip Prototyping Equipment (Universal Laser Systems laser engraving/cutting system, Specac thermal press)

Mould Insert Fab Equipment (Photolithography, Technotrans plating system) - Structuring Equipment (Wittmann Battenfeld injection compression molding system, Hot embossing system)

- Sealing Equipment (Thermal compression bonding system, Ultrasonic plastic welding system, Film laminating system, Solvent roller coating system, Laser bonding system)

- Surface Modification Equipment (Novascan UV/Ozone surface treatment system)

- Quality Control Equipment (Zeta 3D optical profiler, Optical warpage measurement system)

- Chip Prototyping Equipment (Universal Laser Systems laser engraving/cutting system, Specac thermal press)

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)