RESEARCH IN SIMTECH

Metal & Ceramic Forming (MCF)

INTRODUCTION

MCF Group focuses on enabling the manufacturing of near net shape products by using metals, ceramics and composites, as well as multi-material approaches, employing various technologies and equipment, usually as hybrid processes. Industry partners can draw on the expertise within MCG to develop new components or improve existing products by using state-of-the-art material processing technologies and simulation techniques.

Focus Research Areas

- Incremental Metal Forming

- Simulation and Characterisation

- Hybrid Composite Processing

RESEARCH HIGHLIGHTS

- Licensing of Liquid Forging technology: Aavid Thermalloy, Meisterform, Nico Steel

- Industry Joint Lab on near net shape forming technologies: Philips, Dou Yee Technologies

- Industry Alignment Fund projects: Manufacturing of multi-material net-shape parts with heterogeneous properties; Development of high-performance electric traction module

KEY TECHNOLOGIES

- Incremental Metal Forming:

- Die-less forming of large free-form sheet metal parts

- Forming of novel free-from honeycomb sandwich structures

- Thermo-Mechanical Processing (TMP) for lightweight components with enhanced mechanical properties

- Hybrid Composite Processing:

- Hybrid powder forming and gel casting of large dense and porous metal and ceramic components

- Liquid forging of light alloys and metal matrix composites

- Simulation and Characterisation:

- Material characterisation and component analysis

- Processing design and optimisation through advanced simulation

KEY FACILITIES

- Incremental Metal Forming

- 100-ton Servo Mechanical press

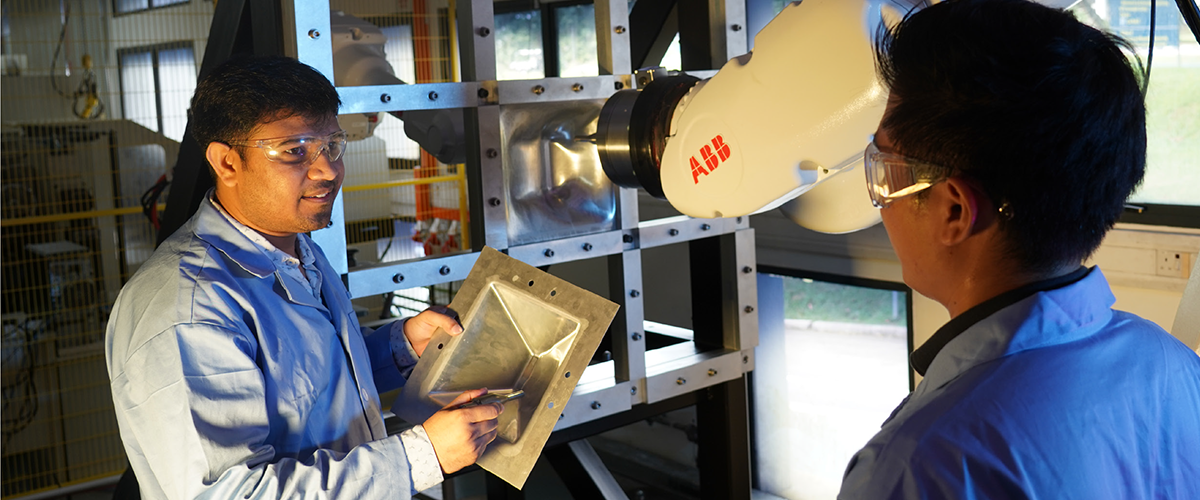

- Robotic die-less incremental forming system

- 2-Ton Servo Press Workstation

- Hybrid Metal and Ceramic Composite Processing

- 400-ton and 1000-ton Liquid Forging system with robotised ladling and melt metering

- Double-barrel metal and ceramic powder injection moulding machine

- Powder extrusion via injection moulding machine

- Freeze/gel/tape casting machine

- Heat treatment and environmentally controlled furnaces

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)