Additive Manufacturing Industrialisation

Technology Overview

Additive Manufacturing Industrialisation offer technologies for Product Life Cycle Management, Cost-Effectiveness, Industrialisation, and Sustainability to achieve a shorter time-to-market. Our strong collaboration with the regional Additive Manufacturing ecosystem enables us to deliver system and part-level design to manufacturing solution development and serve as a one-stop additive manufacturing hub for product owners.

Technology Capabilities

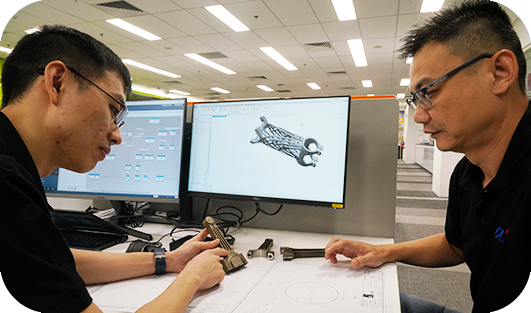

Product Design Development

- Product Manufacturing Process Workflow Development

- Optimisation for Lightweight Structures

- Design for Part Functionality

- Design for reduced Part Count, Post-Processing and Finishing

- Simulations to validate Part Performance

Industrial Applications:

-

Optimised Part Manufacturing Process Value Chain

-

Improved System and Part-Level Functional Performance

Material Performance Management

- Feedstock Material Qualification and Validation

- Correlation of Feedstock Material with Part Characterisation

- Sustainable Material Processing for Metal Powder Reuse

- Optimised Heat Treatment to enhance Part Properties

Industrial Applications:

- Improved Mechanical Properties of End-User Parts

- Material Selection and Part Qualification for Critical Applications

Additive Manufacturing Process Optimisation

- Processability of Metals, Polymer Composites, and Ceramics

- Process Development for Complex Part Manufacturing

- Process Optimisation to Achieve Dimensional Conformance and Defect-Free Parts

- Implementation of a Robust Quality Management System, OQ-PQ

Industrial applications:

- Highly Functional Part Manufacture

- Streamlined Process Steps for Industrialisation

Case Studies

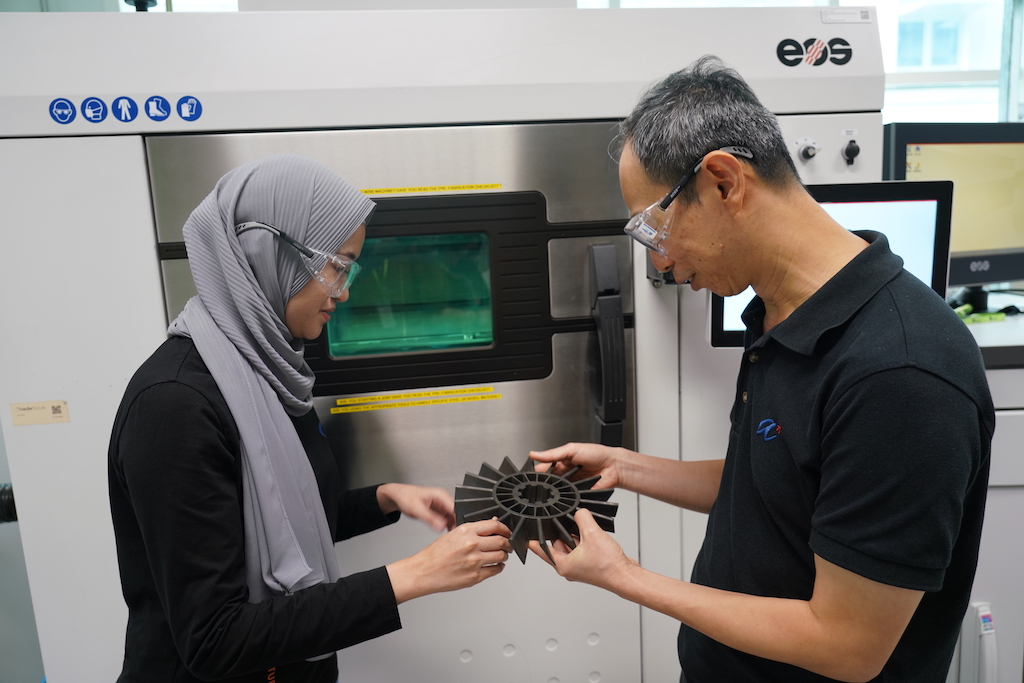

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=2038df88_7)