Autonomous Systems and Robotics

Technology Overview

Autonomous Systems & Robotics focuses on developing core capabilities with the aim of enabling our member’s manufacturing to become more Sustainable, Productive, Agile, Resilient, and Competitive.

These advanced technologies and capabilities accelerate research translation and drive the industrial adoption of simplified and intelligent robotic solutions.

Technology Capabilities

Process Robotisation

- Robotic Process Design and Simulation

- Robotic Surface Processing

- Automatic Toolpath Generation

Industrial Applications:

-

Automated Toolpath Generation from 3D Point Cloud

- Process Robotisation with Closed-Loop Feedback Systems to enable KPVs Optimisation

Mobile Manipulation

- Mobile Manipulation

- Multi-Agent Fleet Management

- Reconfigurable Mobile Robotics

Industrial Applications:

- Multi-Agent Interoperable Platform (Communication with Autonomous Systems and Infrastructure)

- Mobile Robot System for Flexible Material Handling and Transport

- Omni-Directional Mobile Platform

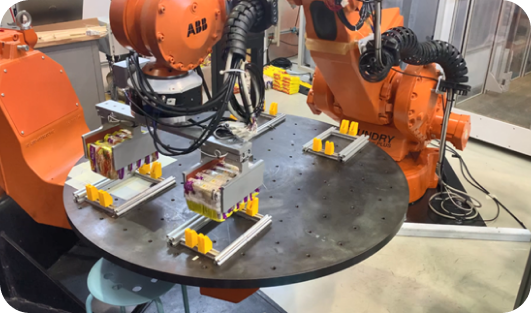

Robotic Systems

- Factory and Line Conceptualisation

- System Architecture and Integration

- System Design, Simulation and Analysis

Industrial Applications

- Robot Cell Design and Process Flow Evaluation for Flexible Line Automation

- End-of-Line Automation and Customisation

Human-Robot Collaboration

- Safety Assured Human-Robot Collaboration and Teleoperation

- Multi-Robot Arms Collaboration

- Learn from Demonstration

Industrial Applications

- Multi-Modal Sensor Fusion for Multi-Robot and Human Collaboration

- Assisted Teleoperation of Heavy Machinery and System

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=2038df88_7)