INTELLIGENT PRODUCT VERIFICATION

Technology Overview

The Intelligent Product Verification Group (IPV) provides industry members with intelligent data- and knowledge-driven solutions. These solutions are designed to automate product characterisation, quality control, process verification, and improvement. IPV exploits leading technologies covering an entire spectrum of wavelengths, from visible to invisible. These technologies are accompanied by advanced data processing algorithms and enhanced with artificial intelligence to create tailored solutions that address the production needs of industry members.

TECHNOLOGY CAPABILITIES

Reconfigurable Inspection System

- Automated In-Line Product-Centric Optical Inspection System Design and Implementation

- Autonomous / Adaptive Inspection Planning

- Inline / In-Situ Surface Characterisation and Sentencing

- I4.0 Ready Integration with Production Line

Industrial Applications

- 100% In-Situ In-Line Product Quality Inspection

- Reconfigurable Inspection System Design and Planning

Non-Destructive Evaluation

- Advanced Non-Destructive Techniques

- X-Ray CT for Volumetric Inspection

- Impedimetric Sensing

- Automated NDT Scanning Solutions

- NDT Simulation (Artist, Civa, Ansys)

Industrial Applications

- Non-Destructive Defect Detection in Metals, Non-Metals, and Composites

- Novel Applications of Sensor Technologies for Part Quality and Process Monitoring

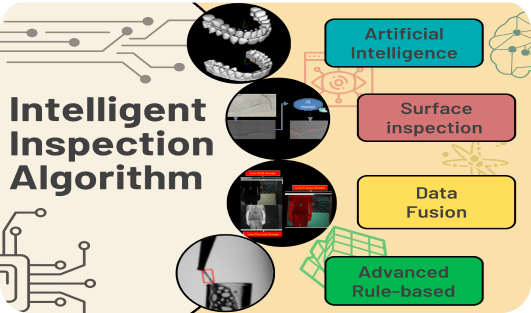

Intelligent Inspection Algorithms

- AI Algorithm for Product and Process Verification

- Advanced Rule-Based Algorithm for Characterisation

- Data Fusion with Multi Source / Modal of Information

Industrial Applications

- Object Recognition and Registration to meet Automation Needs

- AI Model Deployment with Industry Challenges of Unbalanced Data / Few Data

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=2038df88_7)