Remanufacturing Process Technology

Technology Overview

The Remanufacturing Process Technology Group aims to develop advanced deposition and joining technologies to enhance business profitability and sustainability for our industry and R&D partners. The group also has capabilities in total remanufacturing and provides state-of-the-art development in laser cleaning, blasting, and cutting, as well as digitalised solutions in adaptive tool-path generation for machining, multi-modal in-process monitoring, and development of knowledge-based libraries.

Technology Capabilities

Directed Energy Processing

- Perform Component Assessment for Optimised DED Process Selection

- Laser-Ded Of Multi-Materials, Novel Alloys, And Metal-Matrix Composites

- Laser-Ded with Wire and Powder

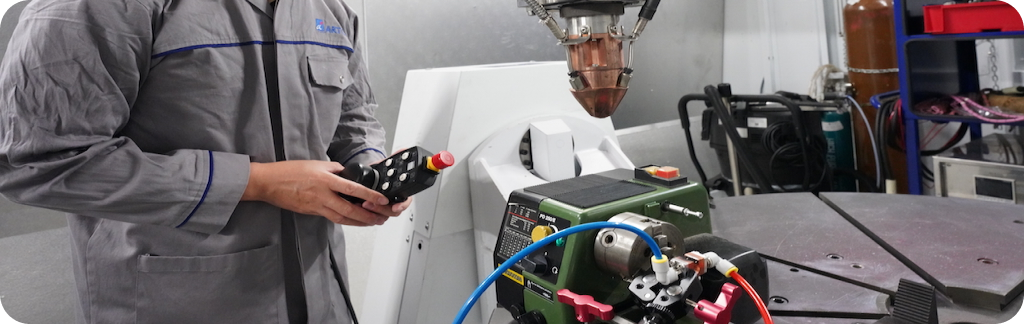

- Wire-Arc Additive Manufacturing

- Hybrid Laser-Arc Welding and Deposition

- Tig and Mig Welding (Plasma Arc Welding)

- High-Pressure Cold Spray Process

- Furnace Brazing

Industrial Applications:

-

Cladding For Hard-Facing, Wear and Corrosion Resistance Enhancement

- Multi-Material Part Fabrication and Advanced Welding

- Repair and Remanufacturing Process

- Cold Spray Repair of TI,Al, Cu, Ni and SS Alloys

- Joining and Bulk Forming of Metal-Polymer Components

Laser Hybrid and Process Digitalisation

- Laser Cleaning/Blasting for Surface Preparation

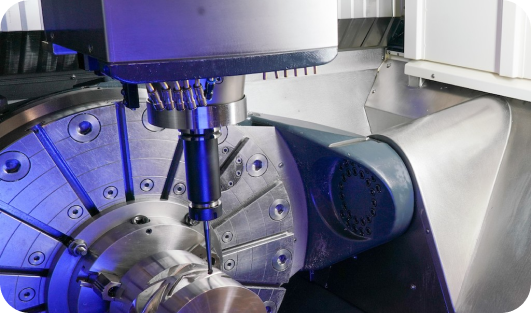

- Hybrid DED and Machining Process and CAM Toolpath Development

- Multi-Modal Process Monitoring and Sensor-Based Adaptation of Hybrid Manufacturing:

- Thermal, Optical, Acoustic Sensors and Robot Position Monitoring

- Melt-pool, Surface Profile and Temperature Measurements

- Thermal, Optical, Acoustic Sensors and Robot Position Monitoring

Industrial Applications

- Cost Effective and Sustainable Alternative to Abrasive Blasting and Cleaning Process

- Sealant and Coating Removal

- Expedite Commercialisation of DED Processes

Adaptive Machining

- Rapid Collection of Data for Adaptive Processes

- Automatic Toolpath Generation for Distorted Components

- Adaptive Robotic and Automation Systems for MRO Applications

- Automation of Repair Processes via M2M Communications

Industrial applications

- Adaptive Pre- and Post-Processing for MRO Applications

- Adaptive Mechanical Material Removal

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=2038df88_7)