Enabling the Next-Gen Tissue Membrane Factory

Science

Growing living cells in a uniform three-dimensional (3D) membrane is valuable for many applications ranging from drug screening to cutting-edge cell and tissue-based therapies and potentially even for food applications such as cultivated meat. Conventional methods rely on complex printing equipment, which are costly and hard to scale up. Our multidisciplinary groups at BTI have developed a simple yet effective spheroid-sheet method that guides small cell spheroids, each containing thousands of living cells, to merge into a large and thin tissue membrane. By mimicking nature’s cell-packing strategy, we make the large-scale, consistent production of tissue membranes more achievable.

Societal Impact

Our spheroid-sheet method is a versatile platform technology that transforms cell spheroids into large, cohesive tissue membranes. It is applicable to a broad spectrum of cell-based products, from skin, cartilage, intestinal, and neural tissue models for drug screening to therapeutic implants. The method requires minimal equipment need, cutting both production time and costs compared to conventional approaches. This simplified, high throughput approach can accelerate regulatory approval and drive down final product expenses, potentially saving tens of millions annually in R&D and manufacturing.

Technical Summary

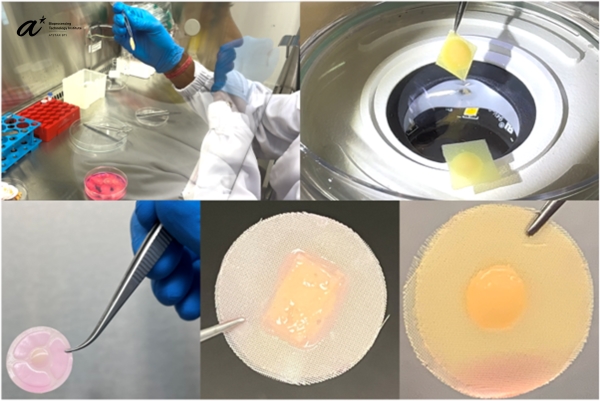

We generated thousands of cell spheroids, each containing 5,000 to 10,000 cells, using an agarose microwell array. After a few days, we transferred the spheroids into our patent-pending Membrane Holding Device (MHD), where they are sandwiched between two thin, porous, bioinert meshes (e.g., nylon or polycaprolactone). A rigid outer frame maintains flatness and defines the final sheet thickness, while the open design ensures nutrient and gas exchange. This configuration confines the cell spheroids into a thin spheroid sheet, encouraging lateral fusion into a homogeneous membrane-like tissue without vertical overgrowth that could impede diffusion.

We have demonstrated the method by producing cartilage-like membranes from human mesenchymal stem cell spheroids in standard chondrogenic medium. Over 7–14 days, spheroids fuse into a 200-800 µm-thick sheet exhibiting a glassy cartilage appearance. Gene and protein analyses confirm high collagen type 2 and aggrecan expression, and histological staining (Alcian Blue, collagen II) reveals abundant extracellular matrix with rounded chondrocytes, demonstrating a successful cartilage-like tissue membrane formation. Under our recently awarded NMRC-IRG grant and in close collaboration with orthopaedic surgeons and clinicians in Singapore, we are further optimizing and evaluating this cartilage membrane, named ChondroMesh, as potential cell-based therapy for osteochondral defect repair.

Our spheroid sheet platform is a versatile foundation for manufacturing a wide variety of cell- and tissue-based products, from skin and intestinal models to neural tissues, pioneering a scalable “Tissue Membrane Factory” approach.

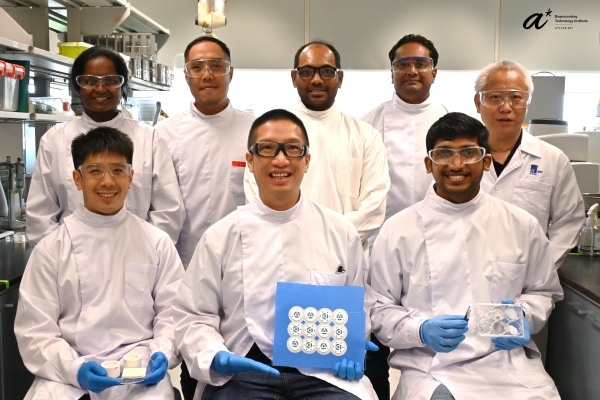

Figure 1. Cartilage tissue membranes produced at BTI using the Spheroid-Sheet platform, which employs a Membrane-Holding Device (MHD) and two thin meshes to fuse cell spheroids into a uniform and thin tissue membrane. This versatile platform technology can be readily applied to develop other type of tissue membranes such as skin, intestinal mucosa, and neural tissue membranes.

References

Le QB, Ezhilarasu H, Chan WW, Patra AT, Murugan P, Venkatesh SA, Tay YK, Lim SR, Abdul Rahim AA, Lee JSZ, Bi X, Choudhury D. A platform for Bioengineering Tissue Membranes from cell spheroids. Materials Today Bio. 2025; 31:101526.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=1a7df424_3)