Modular Programmes (By Specialisation):

Additive Manufacturing

Introduction

3D Additive Manufacturing (AM), which involves building objects layer-by-layer, is one of the most sought-after manufacturing technologies today for high-value engineering applications. This technology offers numerous advantages, including design flexibility and variety suited for high-mix, low-volume production settings. It enables the creation of intricate objects with internal features that would be difficult or impossible to achieve through traditional manufacturing processes such as moulding, casting, forging, or machining. Additionally, 3D AM requires minimal assembly for moving parts. As a tool-less manufacturing process, it provides faster lead times for complex and customised products. All systems within the 3D AM umbrella operate on the fundamental principle of constructing 3D objects layer-by-layer based on each layer’s cross-sectional area.

SIMTech's Additive Manufacturing courses provide a comprehensive understanding of the concepts and fundamentals of 3D AM. These courses cover the principles, methodologies, and applications of specific 3D AM systems, along with essential post-processing techniques for AM products. This knowledge is critical for identifying the most suitable 3D AM technology to manufacture customised and complex 3D parts. The training sessions aim to enhance participants' awareness and interest in adopting 3D AM, equipping them with new skills, knowledge, and technical expertise to remain relevant and competitive in the industry.

Why These Courses

- Designed to meet the specific demands of the Singapore industry

- Delivered by experts in 3D additive manufacturing, both in technology and business

- Highly practical and intensive

Participants will engage with the latest knowledge and current technologies through industrial case studies and facilitated discussions about integrating and implementing AM within their organisations.

Who Should Attend

These courses are intended for professionals, managers, executives, and technicians involved in testing, design, processes, production, reliability, and quality improvement in various manufacturing industries. Target sectors include aerospace, biomedical technology, medical devices, electronics, precision engineering, automotive, and general manufacturing.

For All Modules

List of Modules

Registration

- Please register for this course through our online form: Course Registration Form for Public Classes.

- For the first question, please select "Modular Programmes (Standalone Modules)".

- Applicants will be placed on our waiting list if the course does not have an upcoming scheduled intake.

- When the next intake is confirmed, a confirmation email with payment information will be sent to applicants to finalise their participation.

Schedules

| Modules | Skills Course Reference Number | Next Intake(s)' Training Period (Click on the dates to view their schedules) | Registration Status |

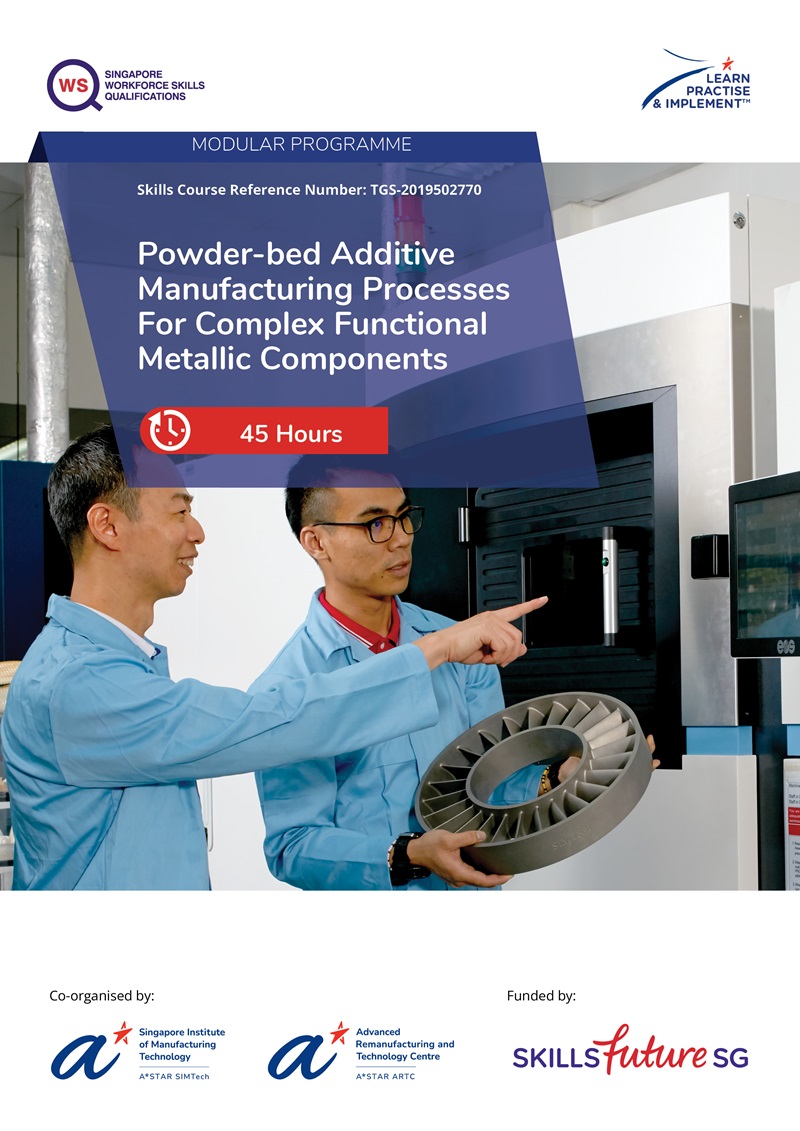

AM M1:

| TGS-2018503489 | The course is temporarily unavailable while the training content is being reviewed. It will be relaunched soon. | |

AM M2:

| TGS-2019502770 | The course is temporarily unavailable while the training content is being reviewed. It will be relaunched soon. | |

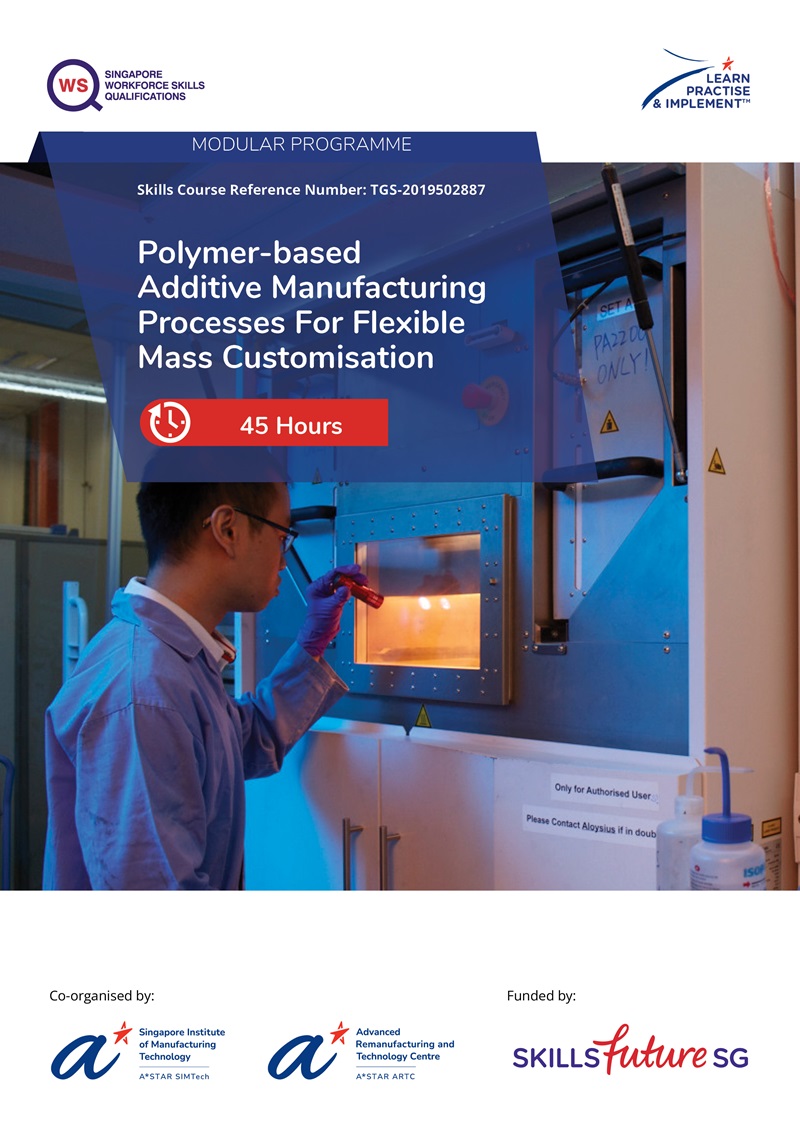

AM M3:

| TGS-2019502887 | The course is temporarily unavailable while the training content is being reviewed. It will be relaunched soon. | |

AM M4:

| TGS-2019503500 | The course is temporarily unavailable while the training content is being reviewed. It will be relaunched soon. |

Note: A*STAR SIMTech and A*STAR ARTC reserve the right to change the class/schedule/course fee or any details about the course without prior notice to the participants.

Announcement:

- From 1 Oct 2023, attendance-taking for SkillsFuture Singapore (SSG)'s funded courses must be done digitally via the Singpass App. More information may be viewed here.

- Participants will be provided with digital course materials when attending our courses. Please note that printed copies will not be available.

: Full day

: Full day : Morning

: Morning : Afternoon

: Afternoon : Evening

: EveningQuick Link

- View the full list of modular programmes offered by A*STAR SIMTech and A*STAR ARTC.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)